|

Brown sugar block

production line

Small brown sugar block production line

Condition overview: the customer plans to produce 7 tons of

brown sugar, according to 24 hours, 0 per hour. 3 tons,

according to 12% sugar yield, Processing 2.5 tons of sugarcane

per hour, the production line is calculated as 3 tons per

hour,To transport, juicing, cleaning, evaporation, boiling

sugar, sand, molding for the entire process, without packaging

machine.

|

Product Name |

Picture |

Basic parameters |

Price (FOB) |

|

Sugarcane conveyor |

|

Nominal groove width: 600mm,

Motor power: 3kw;

Overall dimension: 3500 * 700 * 500mm;

Weight: 260kg;

Quantity: 1 set |

$8,906.00 |

|

Sugarcane cutter |

|

Motor power: 5.5kw

Cane yield 2-3 T / h

Nominal stroke of cutter: 40mm

Voltage: 380V, speed: 710rpm

The distance between cutter and sugarcane belt:

15-25mm

Overall dimension (L) × wide × High): 1280 ×

four hundred and eighty × 720 (mm)

Equipment weight: 760kg

Quantity: 1 set |

$16,125.00 |

|

Sugarcane tearing machine |

|

Maximum processing capacity of sugarcane: 3t/h

Roller speed: 25rpm

Number of rollers: 3

Outer diameter of roller: ¢ 214

Roller length: 400

Motor power: 7.5kw

Voltage: 380V

Motor speed ratio: 29

Size:1.22*0.64*0。89m

Weight:950kg |

$18,531.00 |

|

Double screw cane conveying and impregnation

system |

|

Motor power: 3.0kw

Heating source: steam

Screw speed: 1-2 rpm

Seeping spray head: 2

Processing capacity: 2-3 tons |

$11,181.00 |

|

Three roll sugarcane Juicer |

|

Power: 2.2kw

Processing capacity: 1.5-2 tons

Dimension: 400 * 400 * 600cm

Weight; 235kg

number; 2 sets |

$19,275.00 |

|

Cane

juice filter |

|

Filter bag size: No.3 bag

Diameter: 108mm

Length: 230mm

Treatment capacity: 6 t / h

Filter area: 0.09 square meters

Volume: 1.3L |

$8,971.00 |

|

Cane

juice evaporation tank |

|

Evaporation capacity (kg / h) 2200

Steam consumption (kg / h) ≤ 250

Circulating water consumption (T / h) 6

Steam pressure (MPA) < 0.25

Overall dimension (L x W x H) (m) 4 × one point

five × 3.3;

Quantity: 1 set |

$36,906.00 |

|

Vertical sugar boiling pot |

|

Function: sugar boiling efficiency: 500kg / h,

Heating power: 35kw

Equipment weight: 650kg

Overall dimension: 1500 * 900 * 1700mm;

Quantity: 1 set |

$13,871.00 |

|

Special sanding cylinder |

|

Voltage:380(V)

power:5.75(Kw),Among them, motor power:0.75KW;

volume:200KG /H

bucket size:¢Internal diameter:700,External

diameter:800,Insulation

diameter:900MM;weight:240KG |

$7,265.00 |

|

Installation of pipes and valves |

|

¢ 38

* 2 welded stainless steel pipe with quick

joint:

2m stainless steel pipe, 12 pieces in total

1m stainless steel pipe, 12 pieces in total

0.5m stainless steel pipe, 8 pieces in total

38 stainless steel elbow with welding, 20 pieces

Stainless steel quick fitting joint, 35 pairs in

total,

4 stainless steel milk pumps

Stainless steel washer, 100 pieces

There are 6 sub valves,

Net filter: 4 |

$3,831.00 |

|

Sugar powder machine |

|

Production capacity: 300-400kg/h

Weight: 280kg

Total power: 5.5kw-380v

Overall dimension (mm): 1200 * 1200 * 2100

Quantity: 1 set |

$16,081.00 |

|

Operating platform |

|

Sugar boiling tank, sanding tank platform |

$26,093.00 |

|

TOTAL(FOB) |

$187,036.00 |

Production cycle: 65

working days.

For foreign installation and commissioning, customers need

to bear visa, transportation and accommodation expenses, and

the daily salary of installation and commissioning personnel

is US $120; There are 2 people in total, 15-20 days.

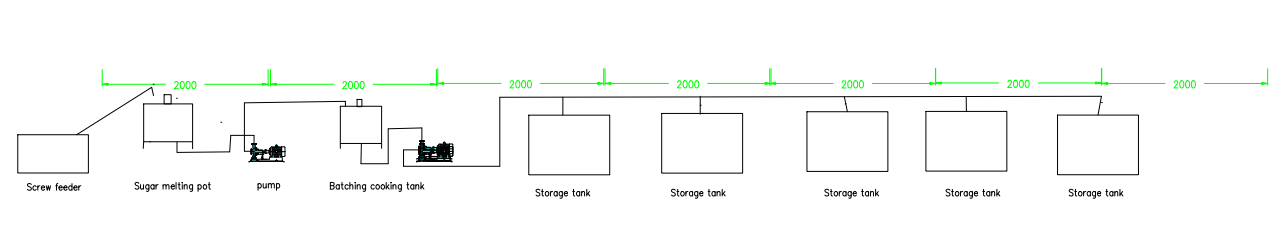

invert sugar syrup production line

(0.5T/H), Capacity 4 ton per 8 hour, Brix 80

|

Product Name |

Picture |

Basic parameters |

Price (FOB) |

|

Spiral feeding machin |

|

Function: feeding

efficiency:1-3M3/H,

infinite speed variation

Motor power:1.5KW

Discharge port from the ground:1700mm

Gross weight:140KG

Dimensions (mm, L*W*H):1100*800*1700MM |

$7,656.00 |

|

sugar melting boiler |

|

Function: sugar melting,

Capacity: 500 kg per hour,

Nominal volume: 600 L,

Power: 30kW,

Overall dimension: 650x650x1200 mm,

Weight: 280kg

Quantity: 1 |

$5,687.00 |

|

Electromagnetic sugar boiling pot |

|

Function: boiling sugar

Nominal volume: 600L

Rated voltage: 380V

Heating power: 60kW

Equipment weight: 350kg

Overall dimension: 1200 * 1100 * 1440mm;

Quantity: 1 set |

$15,093.00 |

|

Electric heating sugar boiling pot |

|

Function: boiling sugar

Nominal volume: 600L

Rated voltage: 380V

Heating power: 60kW

Equipment weight: 350kg

Overall dimension: 1200 * 1100 * 1440mm;

Quantity: 1 set |

$12,031.00 |

|

Stainless steel storage cylinder |

|

300L

stainless steel storage cylinder,

Nominal volume: 300L

Dimension D × H × H1:700 × 700× 1200mm

Mixing power: 0.55kw

Stirring speed: 36R / min

Weight: 180kg

Quantity: 5 sets |

$30,625.00 |

|

Stainless steel syrup pump |

|

Flow

rate: 2T / h

Pressure MQA: 0.6

Diameter mm: 32

Speed: R / min

Power: 1.1kw

Overall dimension: 900 * 400 * 500mm

Weight: 260kg

Quantity: 2 sets |

$6,562.00 |

|

Conventional connecting pipe |

|

Supporting the above equipment |

$2,625.00 |

|

TOTAL(FOB) |

$80,279.00 |

1. Electromagnetic sugar

boiling pot and Electric heating sugar boiling pot, You can

choose any one.

Electromagnetic sugar boiling

pot:The temperature rises quickly when starting;

Electric heating sugar boiling

pot: The temperature rises slowly when starting, and the heat

transfer oil in it needs to be changed regularly.

2. The quotation does not

include packing and filling equipment.

If you need it, we can provide.

3. Production cycle: 50 working

days.

4. For foreign installation and

commissioning, customers need to bear visa, transportation and

accommodation expenses, and the daily salary of installation and

commissioning personnel is US $120.

Flow chart of invert syrup production line

Click the

picture link to enlarge

Invert

sugar syrup production line video

|