|

Automatic

Packaging Machine Of Heavy-Duty Bag

|

One-Line Sealing and

Stitching Automatic

Packaging Machine-TFBK

SERIES

|

|

TFBK-13DC

TFBK-13DC+C5

|

Product Description

TFBK

series one-lined sealing and

sewing automatic packaging

machine, fit for packaging

of single layer Kraft paper,

multi-layer Kraft paper,

paper/plastic laminated bag

.It could automatically

finish the processes of

dust-clean,trimming,stitching,binding

the edge, cutting off, heat

seal, press closure.

This series machines adopt

the advanced technology of

light, electricity, and

mechanism to guarantee its

full automation and high

performance.

There are 9 standard models

for clients selection.

After sealing, stitching,

binding edge, hot pressing,

the sealing performance of

bags is very excellent,

which have the advantage of

dust-proof,moth-eaten proof,

pollution proof and could

protect the packaging

appropriately.

|

Specifications |

TFBK-12C

|

TFBK-13C

|

TFBK-13DC

|

TFBK-14C

|

TFBK-14DC

|

|

Voltage(V/Hz)

|

AC 380/50

|

|

Gross power(KW)

|

3 |

4 |

4.5 |

5 |

5.5 |

|

Sealing power(W)

|

500×4 |

500×6 |

500×8 |

|

Motor power of

sealer (KW)

|

0.4 |

|

Motor power of

sewing machine (KW)

|

0.4 |

|

Speed (m/min)

|

7-10 |

|

Paper tape

|

○ |

○ |

○ |

○ |

○ |

|

Deduster

|

× |

× |

○ |

× |

○ |

|

Applications

|

Thermosol

paper tape |

Three-ply Paper Bag

Thermosol paper

tapePlastic Bag with

Inner PE Film

|

Four-ply Paper Bag

Thermosol paper

tapePlastic Bag with

Inner PE Film

|

|

Dimension(L×W×H)

(mm)

|

2450×1125×1880

|

2650×1125×1880

|

3050×1125×1880

|

2900×1125×1880

|

3350×1125×1880

|

|

Net weight(kg)

|

400 |

450 |

500 |

550 |

|

Specifications |

TFBK-23C

|

TFBK-23DC

|

TFBK-24C

|

TFBK-24DC

|

|

Voltage(V/Hz)

|

AC

380/50 |

|

Gross power(KW)

|

4 |

4.5 |

5 |

5.5 |

|

Sealing power(W)

|

500×6 |

500×8 |

|

Motor power of

sealer (KW)

|

0.4 |

|

Motor power of

sewing machine (KW)

|

0.4 |

|

Speed (m/min)

|

7-10 |

|

Paper tape

|

△

|

△

|

△

|

△

|

|

Deduster

|

× |

○ |

× |

○ |

|

Applications

|

Three-ply Paper Bag

Plastic Bag with

Inner PE Film

|

Four-ply Paper

Plastic Bag with

Inner PE Film

|

|

Dimension (L×W×H)

(mm)

|

2420×1125×1880

|

2850×1125×1880

|

2630×1125×1880

|

3050×1125×1880

|

|

Net weight(kg)

|

420 |

450 |

500 |

• The

minimum distance between the

top of bag and inside

material should be 170mm.

○ = Thermosol paper tape

• Sealing

temperature:0~400℃

△ = Crepe paper tape

• Compressed air

consumption:200NI/min,Pressure:5kg/cm2

× = Not available

• Sealing height:900~1450mm

• Deduster power: 0.6KW

• Exhaust device is

optional.

• Heat seal tape (over

tape) device is available

|

|

|

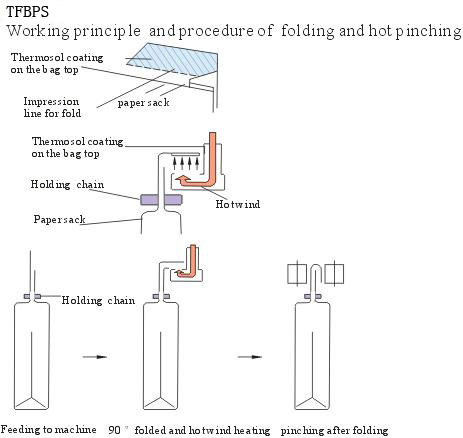

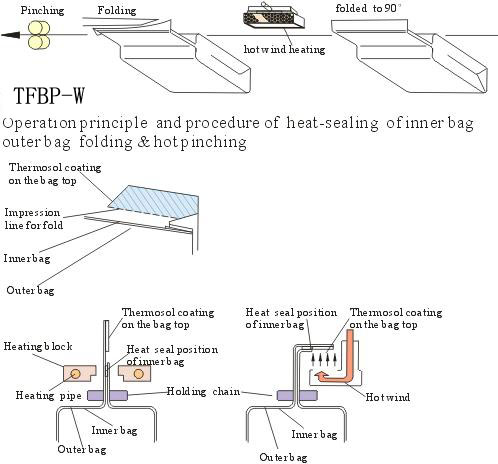

Single or Double Fold

Pinch-Sealing Packaging machine-TFBP

SERIES

|

|

TFBP-3W

|

Product Description

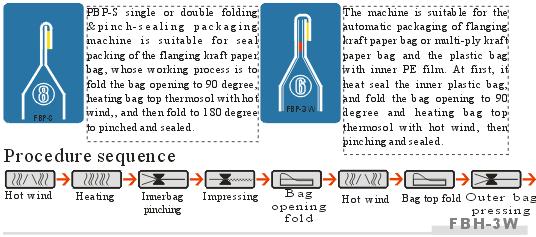

TFBP series

single or double fold &

pinch-sealing machine for paper

sack is suitable for packaging

processes of top edge-folding,

heating, pinching, or processes

of preheating of inner plastic

layer, heat-sealing, sack top

fold, heating, pinching.

This series machines adopt

photoelectric combined

technology, they are

programmable to auto finish bag

top opening, hot wind

preheating, heat-sealing inner

plastic, embossing folded line,

edge folding, hot wind heating

and sack top pinching.

With packaging of this kind of

machines, the packed paper sacks

have the highlights of

sift-proof, strong closure,

dust-proof, moist-proof, mold

free, no contamination, which

makes the materials in sacks are

well protected.

|

Specifications |

TFBP-S |

TFBP-3W |

TFBP-5W |

|

Voltage (V/Hz) |

AC 380/50 |

|

Bag type |

Paper tape |

Paper tape or Plastic

bag with inner PE film

|

|

Speed (m/min) |

6-12 |

|

Transmission speed (mm) |

45 |

50 |

|

Transmission speed (mm) |

750 |

|

Compressed air

consumption (NI/min) |

400 |

800 |

|

Heating power (kw) |

C=2.2 |

A=1.5 B=3 C=2.2

|

A=1.5 B=5 C=2.2

|

|

Dimension (L×W×H)(mm) |

2320×1250×1725

|

3397×1060×1995

|

3384×1280×1790

|

|

Net weight (kg) |

280 |

680 |

|

|

One-Line Sealing and Stitching

Automatic Packaging Machine-TFBF

SERIES

|

|

TFBF-32 |

|

Product Description

This

machine is suitable for

packing paper bag, multi-ply

paper bag and inner plastic

layers. According to the

program, it can finish the

processes of hot sealing

inner plastic bags,

pressing, trimming,

side-line folding and

impress, bag top fold,

packing thermosol paper

tape, pressing paper and

counting automatically,

deduster is optional.

Two types for the position

of sealing inner layers:

Type A sealing position is

at the bag top while Type B

is at the two sides of the

impressing line.

B is applicable to

disconnecting the bottom of

the paper bag, and pock up

the top of the bag, and then

the inner bag will open

automatically. This packing

way is applicable to that

the material of inner

plastic bag and packing

goods are the same. When

need together with the bags,

so that it’s very convenient

for adding material and also

is free of recycling these

packing bags.

|

Specifications |

Type A |

Type B |

|

TFBF-32A |

TFBF-42A |

TFBF-32B |

TFBF-42B |

|

Voltage (V/Hz) |

AC 380/50 |

|

Driving power (KW) |

0.37 |

|

Heatre power (W) |

500×10 |

500×12 |

500×10 |

500×12 |

|

Hot sealing temperature

(℃) |

50-350(adjustable) |

|

Conveyor speed (m/min) |

7-10 |

|

Width of heatseal tape

(mm) |

72(≥80g kraft ) |

|

Applications |

3 layers paper bag,

inner PE film hot

sealing, once bag mouth

folding and pack

heatseal tape |

4 layers paper bag,

inner PE film hot

sealing, once bag mouth

folding and pack

heatseal tape |

3 layers paper bag,

inner PE film hot

sealing, once bag mouth

folding and pack

heatseal tape |

4 layers paper bag,

inner PE film hot

sealing, once bag mouth

folding and pack

heatseal tape |

|

Dimension (L×W×H) (mm) |

2790×800×1880 |

3050×800×1880 |

2790×800×1880 |

3050×800×1880 |

|

Net weight (kg) |

155 |

165 |

155 |

165 |

|

|

Automatic

Edge-Folding

stitching

Packaging

Machine-TFBS-20

|

|

TFBS-20

TFBS-20C+C3 |

Product Description

TFBS-20

automatic edge-folding

stitching packaging machine

is suitable for edge-folding

and stitching of PP, PE

woven bags, it has wide

application in the fields of

foodstuff, feed, chemical

industry.

This machine adopts

photoelectric control

system, which could

automatically and

continuously finish the

processes of edge-folding,

stitching, thread-snipping

etc. of plastic woven bags.

its pneumatic System act the

thread-snipping and lube

spray.

It cam make up an automatic

production line with auto.

ration filling machine and

conveyor.

Optional device:

Edge-folder, 5 digits

counter, alarm of thread

broken.

|

Specifications |

TFBS-20

|

|

Voltage(V/Hz)

|

AC 380/50

|

|

Motor Power of

Sewing Machine (W)

|

400 |

|

Transmission Motor

power(W)

|

180 |

|

Sewing Machine Model

|

GK-35-6 |

|

Height from sewing

machine to floor(mm)

|

750-1280

|

|

Transmission speed(m/min)

|

7-10 |

|

Folding Width(mm)

|

30-40 |

|

Required air

pressure(kg)

|

4 |

|

Compressed Air

Consumption(Nl/min)

|

3.5 |

|

Needle Model

|

80800 200-250#

|

|

Sewing Machine

Specification

|

21S/5,20S/3 Terylene

thread |

|

Height Space Request

of bag top (mm)

|

150-170 |

|

Net Weight(kg)

|

50 |

|

|

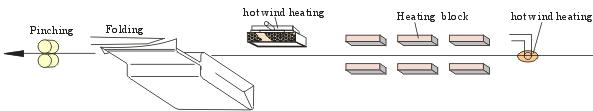

Automatic

Edge-Binding

stitching

Packaging

Machine-TFBS-10

|

|

TFBS-10

TFBS-10B

|

Product Description

TFBS-10

Automatic Edge-Folding stitching

Packaging Machine is suitable

for bag top binding and

stitching of thick paper bags,

it has wide application in the

fields of foodstuff, feed,

chemical industry. This machine

adopt photoelectric control

system, which could

automatically and continuously

finish all the processes of bag

top trimming, paper tape

binding, stitching, paper tape

snipping and thread snipping, of

plastic woven bags. It’s

pneumatic system act the

thread-snipping and lube spray.

It can make up an automatic

production line with auto, gage

filling machine and conveyor.

Optional device: Edge-folder,

5-digits counter.

|

Specifications |

TFBS-10 |

TFBS-10B

|

|

Voltage(V/Hz)

|

AC 380/50 |

|

Motor Power of Sewing

Machine (W)

|

400 |

|

Transmission Motor

power(W)

|

180 |

--- |

|

Sewing Machine Model

|

DS-7C DS-9C GK41 GK95-1 |

DS-6HS DS-9C GK41

GK95-1 |

|

Height from sewing

machine to floor(mm)

|

750-1280 |

|

Transmission speed(m/min)

|

7-10 |

--- |

|

Paper tape Width(mm)

|

50 |

55 |

|

Required air pressure(kg)

|

4 |

--- |

|

Compressed Air

Consumption(NL/min)

|

3.5 |

--- |

|

Needle Model

|

按缝纫机定 |

|

Sewing Machine

Specification

|

21S/5,20S/3

涤纶线

|

|

Height Space Request of

bag top (mm)

|

150-170 |

--- |

|

|