|

Banana chips making machines

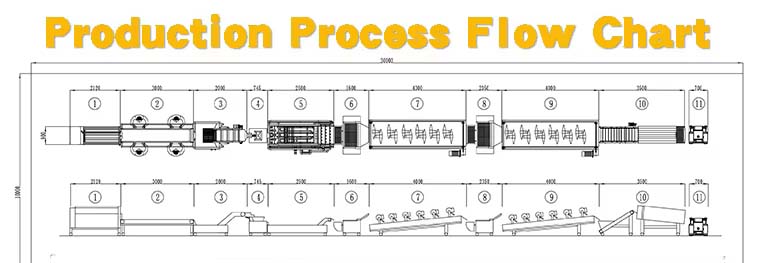

/ Banana Chips production line

Banana Chips production line

The

banana slice processing production line includes

slicing, cleaning, blanching, dehydration,

frying, degreasing, picking, seasoning,

packaging, and other processes.

We

can provide you with professional technical

guidance and formulas to ensure that you can

produce high-quality banana slices.

Production: about

500kg/h

|

Number |

Name |

Type |

Specification |

Quantity |

|

1 |

Banana Cutting

Machine |

YYGQP600 |

Set |

1 |

|

2 |

Rinsing Line |

YYCQX2500 |

Set |

1 |

|

3 |

Blanching Line |

YYLPT4000 |

Set |

1 |

|

4 |

Cooling machine |

YYCQX2500 |

Set |

1 |

|

5 |

Dewatering Machine |

YYFG4000 |

Set |

1 |

|

6 |

Frying Line |

YYWYZ5000 |

Set |

1 |

|

7 |

Cooling Deoiling machine |

YYFG4000 |

Set |

1 |

|

8 |

Frying machine |

YYWYZ4000 |

Set |

1 |

|

9 |

Cooling And Deoiling Line |

YYFG4000 |

Set |

1 |

|

10 |

Picking Line |

YYSS6000 |

Set |

1 |

|

11 |

Seasoning Line |

YYBL3500 |

Set |

1 |

|

12 |

Fully Automatic Packing Machine |

YYDZ420 |

Set |

4 |

Banana slicing machine

The

banana slicing machine is easy to operate, with

high yield. The thickness of the slices can be

adjusted freely, and the cutting angle can be

customized (oblique slicing). The surface of the

sliced banana is smooth and free from breakage.

Bubble cleaning machine

The

equipment is equipped with a bubble generation

device to make the material in a rolling state,

effectively removing starch and impurities on

the surface of the material. Floating debris can

overflow from the overflow tank, and sediment

can be discharged from the sewage outlet to

achieve the purpose of cleaning. Equipped with

variable frequency speed regulation function,

the operating speed can be adjusted according to

the material situation. The automatic lifting

function of the inner liner facilitates the

cleaning of impurities inside the cleaning tank.

It has the characteristics of thorough cleaning,

energy-saving, water-saving, and stable and

reliable equipment.

Blanching machine

Stainless steel mesh belt automatic transmission

frequency conversion speed regulation function,

easy to operate and high efficiency, made of

stainless steel material. The inner liner

automatic lifting device can easily lift the hot

pot, making it convenient to clean impurities

and residues in the tank. The heating part has

automatic temperature control and can be set

arbitrarily. The heat source can be gas heating,

electric heating, and other methods. While

protecting the color, food additives can be

added to ensure that the material has a bright

color.

Dewatering machine/Cooling deoiling machine

The

material is transported through a mesh belt and

flipped multiple times to achieve multiple sides

of the material receiving wind and uniformity of

wind. The high-pressure wind of the fan cools

the food and blows the surface moisture dry. The

conveying speed is adjustable, and the air

nozzle is in the shape of a wind knife,

effectively increasing the air volume pressure,

allowing the moisture of the material to be

blown away or evaporated in a short time,

effectively preventing oil jumping during frying

and shortening the frying time.

Frying machine

The

entire frying assembly line is made of stainless

steel, which is sturdy and durable, and allows

for free temperature control. Adopting electric

heating method, the thermal efficiency reaches

over 95%, saving energy. Equipped with a fully

automatic oil filter for slag removal, there are

no carbonized substances in the oil, and the oil

will not turn black. The service life is long,

and the fried banana slices have bright colors

and good taste, improving the product grade.

Seasoning machine

The

equipment is equipped with a lifting device and

adjustable speed. There is a hopper above the

drum, and the seasoning is evenly and

continuously sprinkled into the drum. The potato

chips are seasoned and mixed by rotating the

drum. There is a leakage net at the discharge

port, which can screen out the remaining

seasoning and collect it for reuse. Not only is

the mixing uniform, but also the integrity of

the potato chips is guaranteed, making it

convenient and practical.

Full-automatic Packing Machine

The

packaging speed :50 packages per

minute,(depending on the quality of the

packaging film and the materials used)

Measurement accuracy: ≤ ± 1.5%

Bag size: (L) 60-300mm (W) 60-200mm

Maximum packaging film width :380mm

The packaging material used in the bag making

form :roll film, and the machine automatically

makes bags with top sealing, bottom sealing, and

back sealing.

Film thickness :0.04-0.09mm

Packaging materials: BOPP/CPP, PET/AL/PE, and

other thermoplastic composite materials

The overall gas consumption :0.8Mpa, 0.5m3/min

The total power of the entire equipment : ten

head scale (1.5KW)+Z-shaped machine (1KW)+main

engine (2.2KW)+0.045KW=4.745KW

Voltage: three-phase four wire 380V 50HZ

|