|

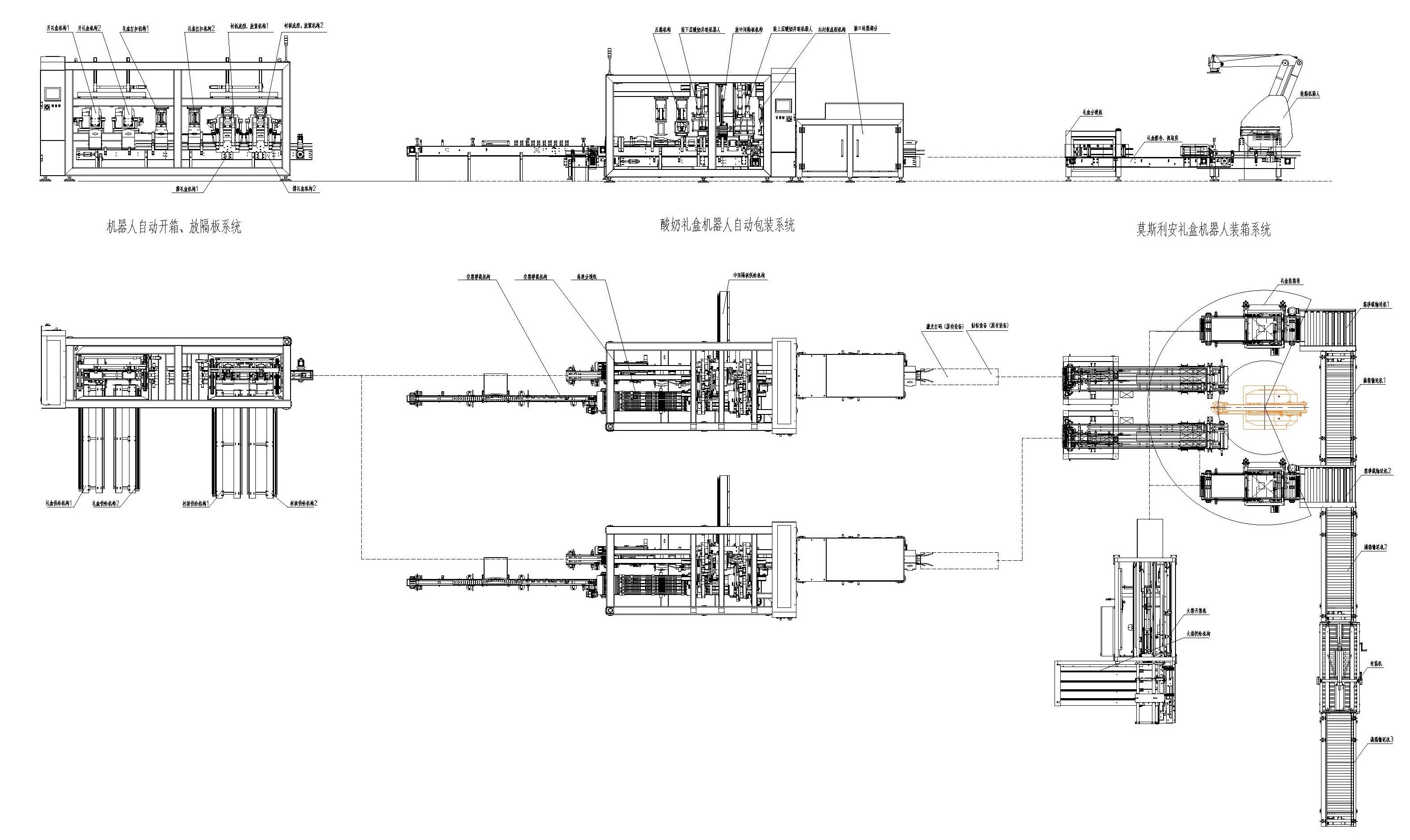

Drilling milk package gift box overall

solution

The

overall solution of the brick and stone milk

package gift box includes the following

parts:

• Gift

box unpacking machine

•

Automatic gift box packaging machine

•

Robotic gift box stuffing system

•

Stacking system

Process specification

1.

Before starting production, the gift boxes,

lining plates and intermediate partitions

should be placed in the material storage

mechanism for use according to specific

requirements;

2.

Unpacking lining board system will open the

gift box and place the lining board, and

then transport it to the packing machine to

wait for the packing of milk bags through

the gift box conveyor;

3. milk

bags are transported to the grasping section

by flexible conveyor and road separator for

grouping and waiting for grasping;

4.The

gift box with liner is prefolded in the

packaging machine by lining, the first layer

is placed, the middle separator is placed,

the second layer is placed, and the lining

is formed.

5. The

milk package is sealed by folding big page,

folding small page, big tongue preforming,

inserting big tongue, uvula preforming, and

uvula inserting.

6. The

sealed gift box goes through the weighing

eliminator, labeling machine, laser code

spraying machine, chain plate conveyor and

finally enters the whole line of grabbing

conveyor to arrange the gift box into the

form of 2X3, waiting for the robot to grab

the big box.

7.

Large boxes are molded and sealed by the

unpacking machine and transported to the

packing area for packing;

8. At

this time, the robot grabs the 6 gift boxes

together and puts them into the big box

through a suction cup and splint gripper.

9. The

large boxes with the gift boxes are finally

put into the robot stacking system through

the code spraying machine and the box

sealing machine to complete the automatic

stacking.

System features:

1. With

Yiyuan industrial robot as the core,

Moselian packaging processes such as

unpacking, lining putting, packing,

clapboard putting and big box loading can be

realized through the robot;

2. The

robot replaces the complex mechanical

structure with simple mechanical structure,

which makes the intelligent packaging system

simple, improves production efficiency,

reduces energy consumption and simplifies

maintenance.

3.

Control system, servo motor, reducer and

other core components are imported brands;

4. Low

loss of packaging materials;

5.The

whole l line is made of stainless steel and

aluminum alloy, which meets the requirements

of food.The whole line adopts sanitary

design, easy to clean;

6.

Robot teaching operation is simple, the full

graphical operation interface conforms to

user characteristics, convenient for on-site

staff operation;The operation data is easy

to set up, adjust, store and transform, and

the daily operation is convenient;

7. The

technological process design of the whole

robot complete set system is reasonable, the

production is continuous and smooth, the

system energy consumption is low, the safety

protection device is carefully designed and

the protection is reliable.

System solution

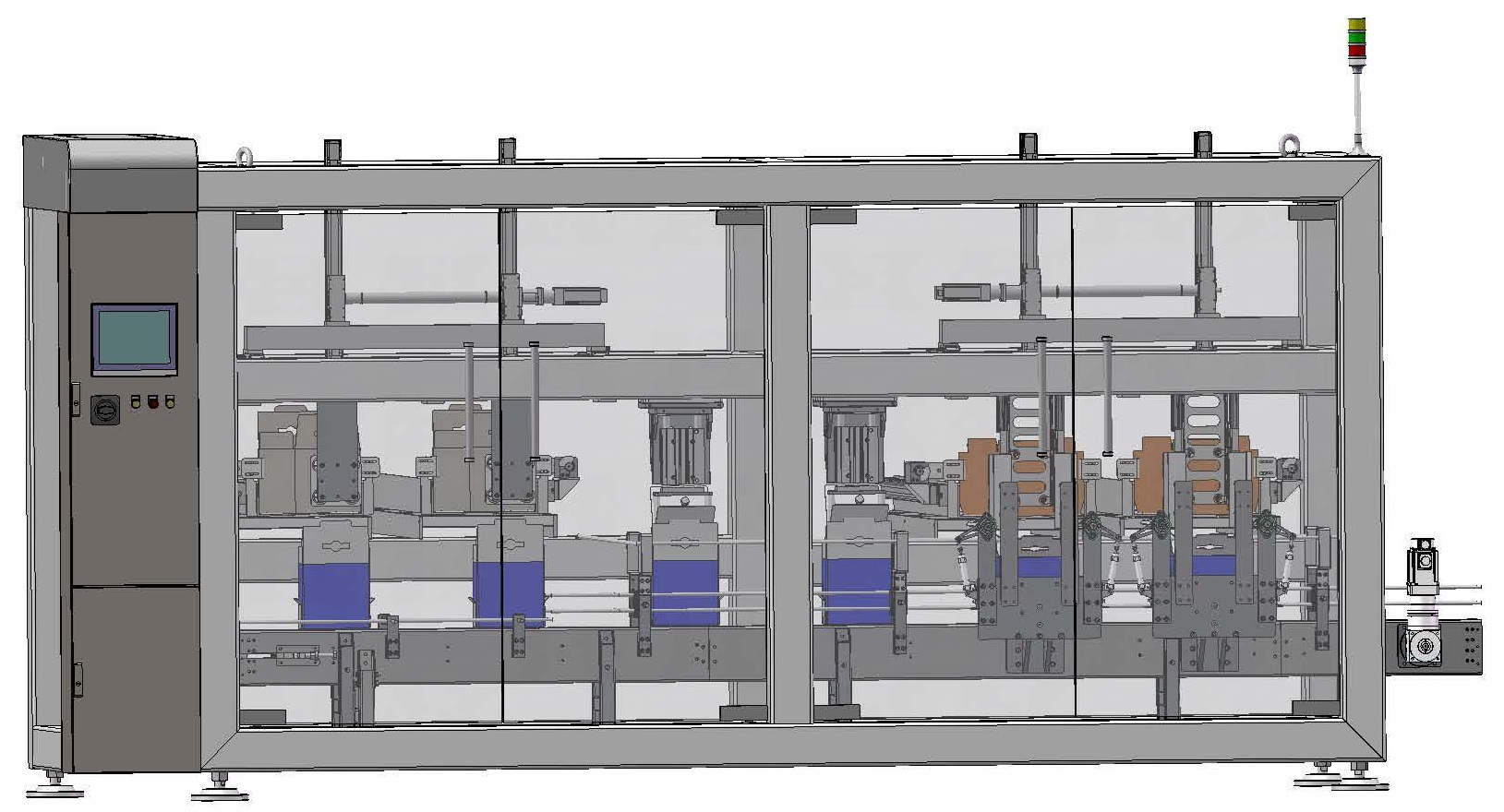

Gift

box unpacking machine

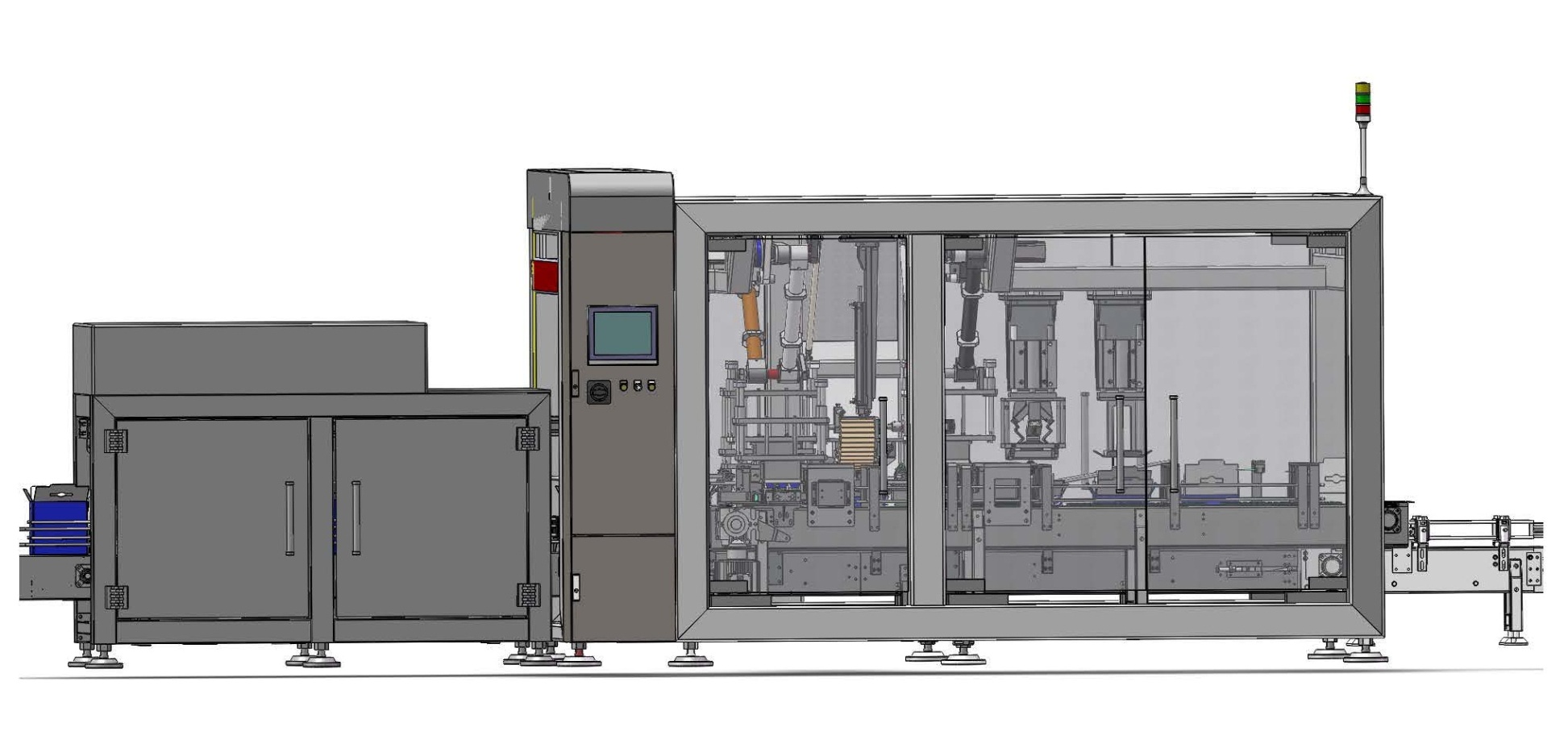

Gift

box automatic packaging

Smart packaging production line

|