|

YIYUAN provides intelligent

manufacturing solutions for

the whole process chain of

intelligent factories in the

ceramic/sanitary industry,

with mature solutions or

cases from the front-end raw

material distribution to the

back-end packing stacking

process.

Solution 1: Glaze pipe conveying system

Project description: the project by

adopting pipeline and glazed pot of

advanced processing technology, realize

the glaze slurry pipeline, solve

traditional glaze slurry transportation

mode capacity big, shortcomings and so

on quality is not stable, on the premise

of guarantee the stability of slurries

properties, quickly and efficiently to

slurries to glazing process, product

quality is stable quality at the same

time, also bring considerable benefits

for the customer.

Solution 2: Gypsum automatic batching

and mixing conveying system

Project description: the project is for

the use of industry automation equipment

to realize the whole process of gypsum

ingredient unmanned, according to the

actual production layout, closely

combining gypsum production technology,

using imported high-precision sensors,

non-standard automation equipment, to

realize automatic gypsum ingredients,

automatic weighing, automatic stirring,

automatic transmission and automatic

cleaning function, to realize unmanned

operation cast integral ingredients

effectively reduce the labor intensity

of workers, improve work efficiency,

reduce dust hazard, achieve the

objectives of the reduced efficiency.

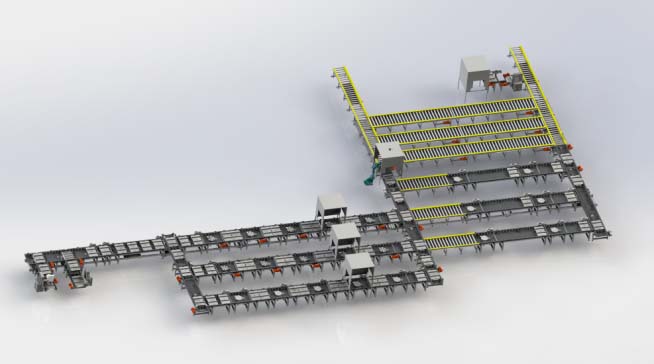

Solution 3: Forming wet blank cache drying

conveyor line

Project description: According to the

extremely limited space of the forming site,

this project adopts simple conveying and

lifting equipment, which can not only meet

the requirements of wet slab drying process,

but also effectively use the site space,

greatly reducing manual handling amount and

labor intensity, changing the mode of

traditional forming process, and realizing

the maximization of production benefits.

Solution 4: Robot dry blank grinding project

Project description: the project adopts the

man-machine collaboration model, combining

with the robot lifting, robots blowing dust,

conveyors, etc., to implement green preform

automatic grinding, automatic lifting, dust

and automatic transmission, and other

functions, the project's innovative is to

use robot instead of artificial dry billet

surface repairing operation, overturns the

traditional sanitary ware manufacturing

process.

Solution 5: Green semi-inspection conveyor

line

Project description: Based on the on-site

process and production demand, this project

adopts power-assisted equipment,

dust-blowing robot, lift and transmission

line, etc., to rationally plan the layout,

realize automatic transmission and flow of

semi-inspection process, greatly reduce the

work load of manual casting, and effectively

solve the problems of customer's factory

logistics and site space.

Solution 6: Robot glaze

line/workstation

Project description: the

project closely with glazing

process requirements, by

integrating glazing robot,

conveyor line, automatic

filling and low glaze

equipment, automatic

cleaning equipment and

drying equipment to

implement green grey

automatic glazing glazing

process (base glaze,

self-cleaning glaze),

automatic filling and glaze,

low automatic brush and

automatic transmission, and

other functions, and

combined the technology of

information system, realize

the seamless joint between

the production data, can

also according to customer's

actual demand in the form of

workstation design, for

customers to maximize the

benefit of the glazing

process.

Solution 7: White blank

warehouse and automatic kiln

loading line

Project description: the

project adopts the conveyor

line in combination with the

three-dimensional form of

library, to boost

inventories, according to

the real-time requirement of

kiln kiln car, ahead of time

for automatic outbound, and

connecting with the robot

automatically loaded into

kiln kiln equipment

products, and docking with

the data real-time

information system, can

realize the real-time

transmission of seting

products, improve plant

operation efficiency.

Solution 8: Automatic

unloading of kiln packing

line

Project Description: This

project combines the

characteristics of small

space and high ambient

temperature of kiln

unloading site, adopts the

organic combination of kiln

unloading robot, elevator

and double-layer conveying

line and the inspection and

packaging line in the rear

section, realizes the high

degree of automation in the

inspection and packaging

process of kiln unloading,

maximizes the number of

personnel in the rear

section, and brings

considerable benefits to

customers.

|