|

YY-600

Automatic two piece sandwich cake.

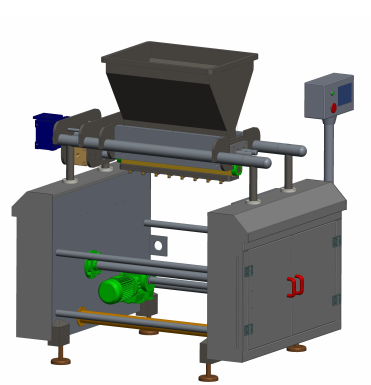

Sandwich square cake production line(Electric 600)

|

No. |

Name |

Model |

Quantity |

|

1 |

Beating mixer |

150 |

1set |

|

2 |

Oil wiping machine |

600 |

1set |

|

3 |

Cake forming machine |

600 |

1set |

|

4 |

Tunnel oven (electric heating) |

600 |

24metre |

|

5 |

Entering the furnace frame |

600 |

1sets |

|

6 |

Furnace discharge rack |

600 |

1sets |

|

7 |

Branding machine |

600 |

1set |

|

8 |

Cooking, dividing, and flipping machine |

|

1sets |

|

9 |

Sorting, longitudinal cutting, sandwich, cake

cutting and forming machine |

|

1sets |

|

10 |

Cream extruder |

600 |

1set |

|

11 |

80L cream mixer |

80 |

2set |

|

12 |

180 degree turning machine |

600 |

1set |

|

13 |

Chocolate coating machine |

800 |

1set |

|

14 |

Frozen tunnel |

800 |

1set |

|

15 |

Cooling and sterilization line |

600 |

18metre |

|

16 |

Automatic material handling and packaging line |

400A |

1 to 2 |

|

17 |

Japanese steel strip |

600*1.2 |

70metre |

2.Introduction to production line equipment:

The two sandwich/cookie

production line consists of an inflatable mixing system, a pulp extruder, an

electric tunnel furnace, branding, cake sorting and conveying, flipping,

sandwich, cake mixing, turning, cooling and sterilization conveying, and an

automatic material sorting and packaging machine

3.Technical

parameters and configuration process flow:

Raw materials ->Mixing ->Cake

extruder ->Tunnel oven ->Branding ->Cake sorting and conveying ->Flipping

->Filling ->Cake merging ->Forming and conveying ->Cooling and sterilization

->Automatic packaging of ingredients

Production Products: Cloud

Cake, Pie Cake, Monochrome Cookies

Main technical parameters:

(1) Compressed air pressure: 0.6-0.8mpa

(2) Compressed air usage: 0.5-0.7m ³/ Min

(3) Total power of the entire line: 58KW+thermal power (280KW)

(4) Voltage: according to local customers (customized for motors)

(5) Production capacity: Cake: 200-300KG/H (calculated at 20g/piece, width 30cm,

length 63cm)

(6) Baking time: Depending on the food

(7) Cake weight: customer defined

(8) Working width: 600mm

4.Equipment

technical parameters and configuration:

1. Beating

mixer / 1set

Production capacity: 500KG/H

Density error: 0.03, specific gravity: 0.4-07

External dimensions of the cylinder: 800 * 800 * 1290mm. * 2 pieces

Weight: 560kg, Motor power: 28kw

Capacity: 150L

Passing time: 6-8 minutes per time, 25kg of powder per time

Cold water circulation pressure: 4ig

Refrigerator model: 13000 kcal

Electrical configuration: PL central programmable control

The diameter of the stainless steel conveying pipe is 38mm, and the water pipe

interface is made of stainless steel pipe material

1. One set of 150L mixing and mixing drum

1.1 Mixing drum 304 material with a thickness of 2.5mm can be filled with

cooling water in the middle of the double layer cylinder, making the temperature

of the drum controllable.

1.2 Mixing Ball 304 Material 1 Wire Diameter 8MM

1.3 Inner wall blocking with 10 surge plates installed

1.4 304 stainless steel anti discharge cover plate, installed with safety

switch. 1.5 Double layer insulation barrel body, capable of passing cooling

water.

1.6 Cylinder size: 900 * 700 * 1200mm

1.7 Motor power: 5.5kw

1.8 RPM 20-120 RPM (adjustable)

1.9 Air can be added to dispel.

1.10 One set of rotor pump installed

2. One set of storage buckets

2.1 Storage bucket material thickness 2.5mm 304 stainless steel material

2.2 Double layer cylinder stainless steel cover, 1 for cooling water.

Insulation.

2. Oil wiping machine

/ 1set

Power: 0.25 kW

Size: 1200 * 270 * 350

Stainless steel heating oil hopper

Oil wiping motor: 0.37KW

3. Cake forming machine

/ 1set

Motor: 2

Mobile forming machine head: 1 unit

Oil brushing device: 1 set

Frequency converter: 2 units

Material bucket: 1 unit

Adjusting screw: 1 pair

Squeezing drum: 1 unit

Adjustment table: 1 piece

4.

Entering the furnace frame /

1set

1. Manufacturing of

rack 12 # channel steel.

2. Steel belt cylinder tightening

3. One set of deviation adjustment device

4.Passive drum diameter 800mm, width 700mm

5. Synchronous gear.

5. 600 Tunnel oven

36 meters

/ 1set

Electric oven

configuration:

A. Length 36 meters, appearance 1.2MM stainless steel.

B. The steel strip (Japan) is 1.2MM thick and made of high carbon steel.

C. The front and rear steel strips are automatically adjusted for deviation and

an automatic alarm is triggered.

D. Total heating power: 660KW

Temperature zone electric heating tube distribution:

Zone 1 120 * 1.8KW=216

Zone 2 120 * 1.5=180KW

Three zones 120 * 1.2=144KW

E. Automatic temperature control, equipped with temperature limiting device,

automatic alarm, and adjustable upper and lower fire temperatures

F. The shell has a 250 thick stainless steel insulation layer, filled with

high-density mineral wool.

G. Install scraper and steel strip cleaning device

H. Install 4 dehumidification fans

I. The frame is made of carbon steel square tubes, with high density and

high-quality mineral wool for insulation

External dimensions: 36 meters * 1.5 meters * 1.6 meters

6. 600 Furnace

discharge rack

/ 1set

1. Manufacturing of

rack 12 # channel steel.

2. Shell made of 304 stainless steel

3. 1 set of manual deviation adjustment device

4. Passive drum diameter 800 wide 700

5. One set of 3KW gear driven SEW motor.

7.

Branding

machine / 1set

1. This machine

adopts a computer display screen operation, which is simple and easy to

understand.

2. Electrical PLC intelligent control,

3. Each branding head has adjustable temperature control, with a temperature

range of 00-400 degrees, and can track and locate the branding. The branding

time is adjustable.

4. Production capacity: 2 seconds per stroke, driven by the servo motor

tracking,

5. Using an extruder signal source, synchronized with the extruder.

6. This machine is equipped with a tunnel furnace transmission proportional

motor and a branding machine synchronous root palm synchronization, and is

equipped with a screw module. Speed up, adjustable itinerary.

7. The imprinting machine head follows the left and right movement of the steel

strip, and is equipped with left and right guide wheels.

8. The branding head is driven by a servo motor to increase reaction speed.

9. The equipment is equipped with a protective cover and an outer shell made of

304 stainless steel to ensure safety.

10. The equipment is equipped with a heat exhaust fan to reduce the working

temperature of various components.

8.

Cooking,

dividing, and flipping machine / 1sets

Rack 304 stainless

steel

Conveyor plate 304 stainless steel

Conveyor belt PU

Two stage conveying motor 0.75KW

Cake flipping servo motor 0.75KW

Stainless steel partition

Cake releasing cylinder

Technical parameters:

Power: 0.75KW

Size: 1200 * 880 * 800

Weight: 120kg

9. Sorting, longitudinal

cutting, sandwich, cake cutting and forming machine / 1sets

Organize cylinders

and synchronize tracking

Clamp machine synchronous tracking, frame made of stainless steel, working width

600

Two 1.5KW servo motors

Synchronous tracking of cake suction machine. Adopting vacuum principle for cake

suction, silicone suction head 1.5KW servo motor

Conveyor 1.5kw, PU conveyor belt

Working width 600. Stainless steel frame.

10.

Cream extruder / 1set

1. Aluminum alloy

extrusion box

2. The PE rotor principle extrudes cream.

3. One gear motor with a capacity of 2.2KW

4. Composition of movable extrusion nozzle

5. Power 4.75KW

6. Size: 1200 * 800 * 1800

7. Weight: 700KG

11.

80L cream mixer / 2set

Automatic lifting,

variable frequency control for gear shifting, touch screen operation, egg ball.

Material cylinder made of stainless steel

1. Power: 4.75KW

2. Size: 1200 * 800 * 1800

3. Weight: 700KG

12.

180 degree turning machine / 1set

A. 1 PU conveyor belt

B. 1 frequency converter

C. 1 SEW motor

Technical parameters:

Power: 2KW

Size: 1600 * 1600 * 800

Weight: 450kg

13.

800 chocolate coating and freezing tunnel / 1set

Belt width (mm):

600mm;

Belt speed (m/min): 1-6;

Refrigerator (one set): 3 sets;

Cooling tunnel length (meters): 16 meters;

Tunnel temperature (℃): 2-10;

1. Stainless steel welding of the rack

2. PU conveyor belt, with two cooling fans installed in the front section.

3. Rubber drum drive

4. Equipped with a 5-horsepower compressor,

5. There is a stainless steel organic glass insulation cover on top

6. Temperature adjustable from 5 to 15 degrees

7 Power: 8.2KW

8. Overall dimensions: 9000 * 1800 * 1200

9. Working width: 800

14-15.

600 sterilization conveyor line / 1set

A. Stainless steel frame, stainless steel

conveyor plate

SEW motor: 1.5KW: 1 set

C. Drive frequency converter

D. PU conveyor belt

D. Sterilization device

16.

Automatic material handling and packaging line (One to two) / 1ses

Material processing

line parameters:

Speed: 0.9m/mim

Power: 3.5kw

Weight: 200kg

External dimensions: 3000 * 900 * 1100mm

Packaging machine parameters:

Power: 3.4kw

External dimensions: 4000 * 920 * 1600mm

Weight: 550kgs

Bag making length: 65-160 mm, bag making width: 35-100mm

Product height: up to 35mm

Packaging speed: 50-250 bags/minute

Packaging film width: 250mm

Material: The frame is made of A3 carbon steel and in contact with food, it is

made of 304 stainless steel.

17.

steel strip

70000*600*1.2

Material: High carbon steel.

|