| Chocolate Drip Drop Machine

Use: dipping

chocolate chips.

Model: CTNYQYH400-1200

Capacity:2-2.5T/shift

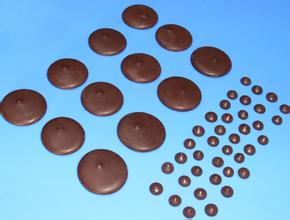

Chocolate chips depositing machine

USE:

1).The chocolate chips depositing machine is used for

producing particle chocolate chips. It can produce

chocolate chips with a tail on top (like water drops),

it can also produce chocolate chips without a tail on

top (like button).

2).The size and weight of chocolate chips can be

adjustable as per client's requirement.

3).The chocolate chips depositing machine comprise of

depositor and cooling tunnel. It is controlled by PLC

system.

Main parameter:

1).Width of conveyance belt: 600mm

2).Speed of conveyance belt: 1~3M/Minute

3).Working temperature of tunnel: 0~10 degree Celsius

4).Depositing speed: about 20times/minute

5).Cooling compressor: COPELAND brand

6).Diameter of chocolate chips: 4~12mm adjustable

7).Weight of chocolate chips: 0.1~2g adjustable

8).Net Weight: 2500kg

9).Size of Machine: 13000*960*1720 mm

Main structure and working principle:

1).The chocolate chips depositing machine is

comprised of depositor and cooling tunnel.

2).The depositor is comprised of chocolate paste

depositing structure, conveyance belt lifting structure,

frame etc.

3).The chocolate paste is fed into the hopper with

thermal insulation temperature.

4).The chocolate paste is deposited on the conveyance

belt by the depositing parts and then transported to the

cooling tunnel by the conveyance belt.

5).The cooling tunnel is comprised of 6 segments, the

cover layer adopts thermal insulation painted steel

plate which can be opened, and get the best cooling

effect.

6).The cooling air is from the external refrigeration

compressor, the evaporator makes up the circulation of

cooling air. When the refrigeration compressor is

working, the evaporator emits heat. Turn on the blower,

the cooling air from the evaporator is sent to upper

position of the middle color plate in form of cooling

air to cool the chocolate chips and sent to lower

position of the middle color plate through self-suction

of the blower, then through the evaporator to realize

circulation of cooling air, so that to avoid loss of

cooling air and increase cooling efficiency of the

refrigeration compressor.

7).After refrigeration starts working and temperature

in the upper position of cooling tunnel reaches 5~10

degree Celsius, the chocolate chips can enter the

cooling tunnel.

8).The conveyance belt is used to convey chocolate

chips on the conveyance belt into the cooling tunnel for

cooling.

|