|

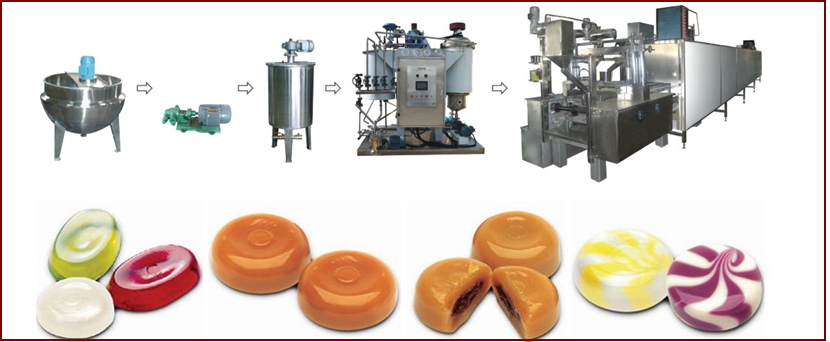

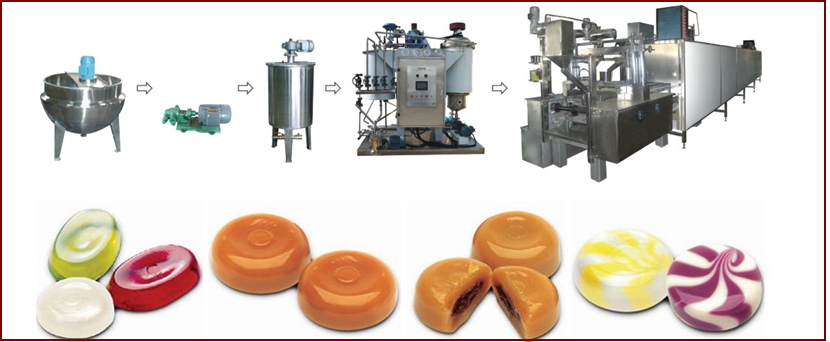

Working process

|

|

|

|

Parameters

|

|

|

MODEL |

CTNYQYH150 |

CTNYQYH300 |

CTNYQYH450 |

CTNYQYH600 |

|

Capacity(kg/hr) |

150 |

300 |

450 |

600 |

|

Max candy weight |

6g |

6g |

6g |

6g |

|

Depositing speed |

55-65n/min |

55 |

65n/min |

55 |

|

Compressed air requirement |

0.2m³/min,

0.4-0.6Mpa |

0.2m³/min,

0.4-0.6Mpa |

0.2m³/min,

0.4-0.6Mpa |

0.2m³/min

,0.4-0.6Mpa |

|

Working condition |

Temp:20-25℃

Humidity:55% |

Temp:20-25℃

Humidity:55% |

Temp:20-25℃

Humidity:55% |

Temp:20-25℃

Humidity:55% |

|

Total Power |

18kw/380V |

27kw/380V |

34kw/380V |

38kw/380V |

|

Total Length |

15m |

17m |

17m |

20m |

|

Total Weight |

3500kg |

4000kg |

4500kg |

5000kg |

|

YY-600 FULL AUTOMATIC HARD CANDY

DEPOSITING LINE

(4 ROWS, 600KG/HR)

MODEL: YY-600,

CAPACITY: 600KG/HR, COMPLETE PRODUCTION LINE

FUNCTION: SINGLE COLOR, DOUBLE

COLOR, CENTRAL FILLING, STRIPE TWO COLORS HARD CANDY MAKING

OUR STRONGPOINTS:

PLC /computer process control available; LED TOUCHES Screen.

Optional (mass) flowing controlled by Frequency inverters ;

In-line injection, dosing and pre-mixing techniques for the

proportional addition of liquid(milk); Dosing pumps for the

automatic injection of colors, flavors and acids;

1. EQUIPMENTS LIST

|

S/N

|

DESCRIPTION OF GOODS |

DIMENSION(mm) |

QTY |

|

(l*w*h) |

(SET) |

|

1 |

500L SUGAR

DISSOLVING TANK

(STEAM HEATING) |

Ø1320*1140 |

2SETS |

|

2 |

500L SYRUP STORAGE

TANK |

Ø1000*1700 |

2SETS |

|

3 |

SYRUP TRANSPORTING

PUMP |

600*450*400 |

3SET |

|

4 |

600KG PLC CONTROL

CONTINOUS VACUUM MICRO-FILM COOKER |

2600*2000*2500 |

1SET |

|

5 |

COLOR/ESSENCE MIXER

|

1000*300*450 |

2SETS |

|

6 |

AUTOMATIC DEPOSITING AND COOLING TUNNEL

(THREE ROW)

6.1-Automatic 4ROWS Depositor Machine

6.2-Cooling Tunnel

6.3-Automatic Remolding system

|

12000*2650*2100 |

1SET |

|

7 |

HARD CANDY MOULDS |

320*75 |

1000PCS |

|

9 |

HIGH SPEED PILLOW TYPE HARD CANDY PACKAGINIG MACHINE

|

2900*1305*1586 |

2SETS |

|

|

2. TERMS&WARRANTY

Loading Port: Shanghai

Seaport. Container

Required: 1*40HQ

Delivery time:

60 work days from receiving advance

Packing:

Seaworthy wooden packing

Guarantee installation:

1)Guarantees

the quality of production for 2 years since the date of

installation.

2) Seller send engineer for installation, worker training and

provide recipes. Engineer’s round-trip tickets, local board

loading will be buyer’s cost. The testing will be persons for 15

days. Cost 80$ per day per person.

3. MAIN

PARAMETER

|

Capacity(kg/hr) |

600 |

|

Candy weight |

Customer provide |

|

Depositing speed |

55-65timesmin |

|

Steam Require

|

500kg/hr 0.5-0.8Mpa |

|

Compressed air requirement |

0.2m³/min, 0.4-0.6Mpa |

|

Working condition |

Temp:20-25℃ Humidity:55% |

|

Total Power |

38kw/380V |

|

Total Weight |

5000kg |

4. PRODUCT SAMPLE FROM THIS LINE

5. EQUIPMENT SPECIFICATION

1). 500L

SUGAR DISSOLVING TANK (STEAM HEATNIG)

|

Function: Melting the white sugar

with glucose and water

Material: ss304 ( jacket tank with steam heating)

Mixing Motor: ABB brand.

Other electric components: Siemens

Dimension: Ø1320*140mm

Working temp: 120℃

Working pressure: 0.15Mpa

Power: 0.55kw(Steam Heating)

weight: 200kgs

|

2). 500L SYRUP STORAGE TANK

|

Function: To keep the syrup in

constant temp

Material: ss304 ( jacket tank with steam heating)

Mixing Motor: ABB brand.

Other electric components: Siemens

Volume: 500L

Dimension: ¢1000*1700 mm

Power: 0.55KW

weight: 150kg |

3). SYRUP

TRANSPORT PUMP

|

Function: transport syrup

Driving Motor: ABB Brand

Pump: Boge ( China repute brand)

capacity: 3.3m³/h

Pressure: 0.32Mpa

Power: 1.5kw

Weight: 40Kg |

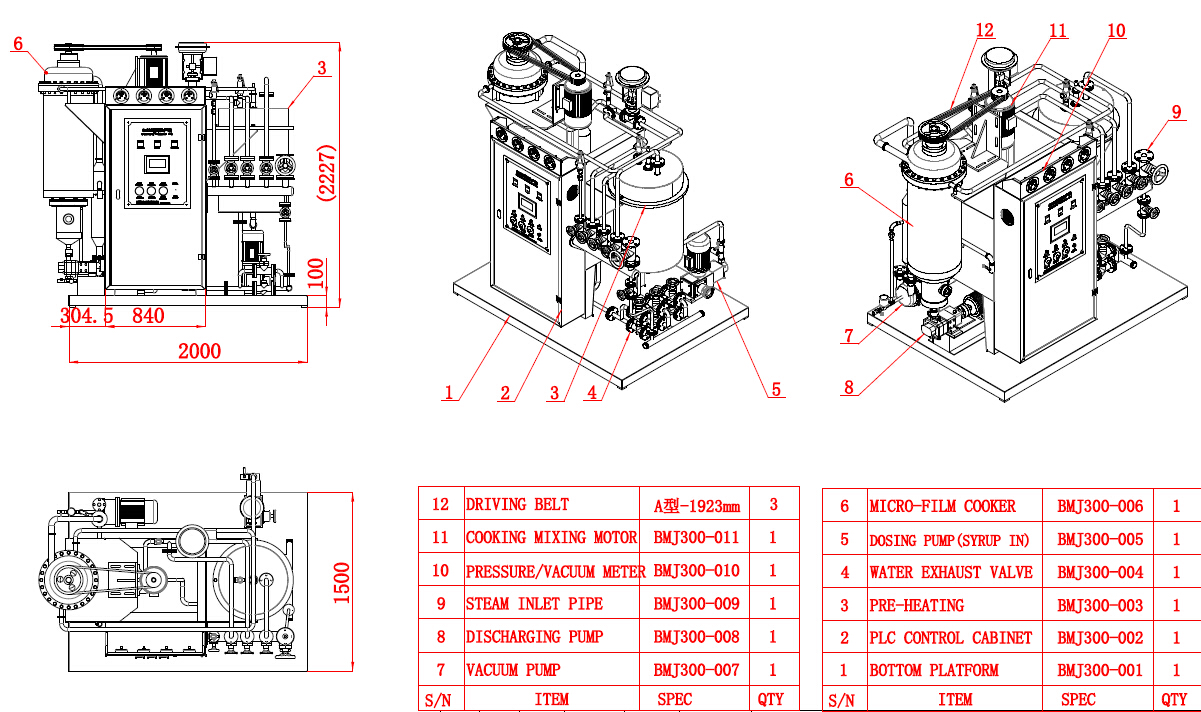

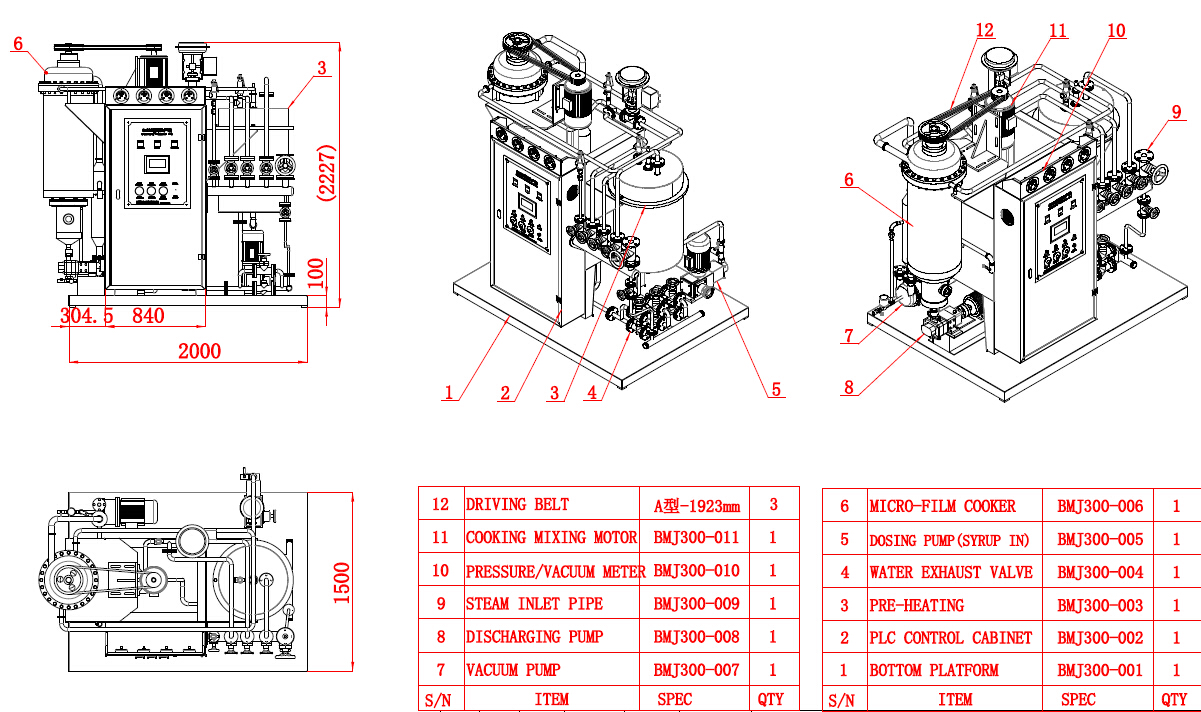

4). 600KG PLC CONTROL CONTINOUS VACUUM MICRO-FILM COOKER

|

Function: Vacuum Micro-film type

cooking, Make the temperature reach more than 140℃

composed of dosing pump, pre-heater, cooking chamber,

vacuum pump, discharge, pump, pressure and temperature

instrument and PLC control system

Motor: ABB brand. Electric components: Siemens brand

PLC: Mitsubishi Touch Screen: Siemens

capacity: 600kg/hr

Steam Consumption: 250kg/hr

Steam Pressure: 0.5-0.8Mpa

Power: 17.2kw

Dimension: 2600*2000*2500m

weight: 1400kg |

|

COMPONENTS

|

5). COLOR/ESSENCE MIXER

|

Function: Mixing the syrup with

different flavor and colors

Mixing motor Brand: ABB brand

Dosing pump: R-Dose, Germany

Includes: Two mixer and 4 pumps

Dimension: 1000*300*450mm

weight: 50kgs*2

power: 0.55kw*2 |

6). AUTOMATIC DEPOSITING AND COOLING TUNNEL (3 ROWS)

|

Automatic depositing and cooling tunnel

is composed of :

Automatic depositing head machine

Automatic remolding

Automatic cooling cool tunnel

Dimension:12000×2650×2100MM

weight:5000KGS

power:35.5KW |

|

6-1 AUTOMATIC DEPOSITING MACHINE

Function: Filling the syrup on the

moulds, able to do one color/two color/center filled

candy etc.,

Material: Outside: SUS304

Food contact surface:sus304

Electronic Motor: ABB brand. Air Cylinder: NSK

Other electric Parts: SIEMENS BRAND |

|

6-2/6-3 AUTOMATIC REMOLDING

MACHINE AND COOLING TUNNEL

Function: Automatic Remolding and

Cooling down the products.

Material: Machine Frame: Full SUS304, PU conveyor belt.

Panel/frame all insulated

Electronic Motor: ABB brand.

Other electric Parts: SIEMENS BRAND

Refrigerators:7.5HP*2Sets ,Copeland,USA ,Water chiller

|

7). HARD CANDY MOULDS

Function: For

Candy Shapes. Size and shape provided by clients

Material: Aluminum coating with Teflon

8). HIGH SPEED PILLOW TYPE HARD CANDY PACKAGINIG MACHINE

|

Function: Square, Ellipse, Oblate,

Globular, Plum Blossom-Shaped pillow packing machine

Film Material: OPPCPPPET Metalized film, Al-plastic

film, Paper-rubber complex

Packing spec: (Length)12-40mm (Width)12-30mm

(Height)5-18mm

Capacity: 500-600pcs/min

Gross Power: 3.7kw

Overall Dimensions: 2900*1305*1586mm

Gross Weight: 500kg |

CTNYQYH-150 HARD CANDY DEPOSITING LINE