Brief Introduction of Tea Drinks

Finished Products

Tea drinks are mainly made of

extracted liquid of tea leaves,

tea powder and concentrated

liquid. It is a kind of soft

drink with some natural tea

polyphenols and theine which are

components of teas. Tea drinks

have the particular flavor of

tea as well as healthy and

nutrient efficacy like it of

flower tea, green tea and oolong

tea, etc.

Processing Technique of Tea

Drinks

a.

Pure water preparation: the

original water is from ground

water, tap water, spring. The

water is treated by double-layer

reverse osmosis treatment so

that water can achieve the

following standard:

Conductivity≤10us/cm

Percent recovery:75%

Operation pressure: 1-1.5Mpa

b.

Tea juice distilling technology:

fresh tea leaves or fannings are

selected and washed clear and

then are squeezed, distilled and

centrifuged to get the tea

juice. The juice are infused

into sugar, acid, essence and

pigment and then mixed with pure

water prepared in last procedure

for infilling tins. After this

procedure, the finished product

fits for the following

standards: Tea juice

content≥10%(m/v);

Tea soup (inputting

temperature≤30℃) is treated at

the temperature of 121~137℃ by

special UHT sterilizer to keep

the table temperature for 5-30s

so that it become asepsis

material then this material is

cooled to 85-92℃ and sent into

infilling machines.

c.

Air purification of infilling

area: the air treated by filter

is pushed into infilling area to

achieve a 100,000 level (static

state) purification standard.

d.

Purging of PET bottle: the inner

surface of PET bottle is flushed

repeatedly by sterile water and

sent to infilling area.

e.Bottle infilling and cap

sealing: asepsis material is

pre-filled into treated PET

bottle and sealed by Capper to

be semi-finished products.

f.

Inverted sterilization of

semi-finished products: sealed

bottles are sent to inverted

carrier chain which can makes

these bottles slant at 110

degree at the same time they are

vibrating together with tracks

so that the bottle caps are

sterilized again by their own

temperature. In this procedure

the cap gaskets are softened and

the sealing degree is higher.

This inverted period is

approximate 30-45s. After

sterilization, the carrier chain

can make bottles upwards

automatically.

g.

Cooling of semi-finished

products: the products after

inverted sterilization are

transported to tracks for

cooling and spraying by

circulating water (4 times)

until they are kept below 40℃.

Before they are taken out,

bottle bodies are washed by pure

water.

h.

Post-packing for the products:

blowing dry; label shrinking and

gluing; date printing;

light-check.

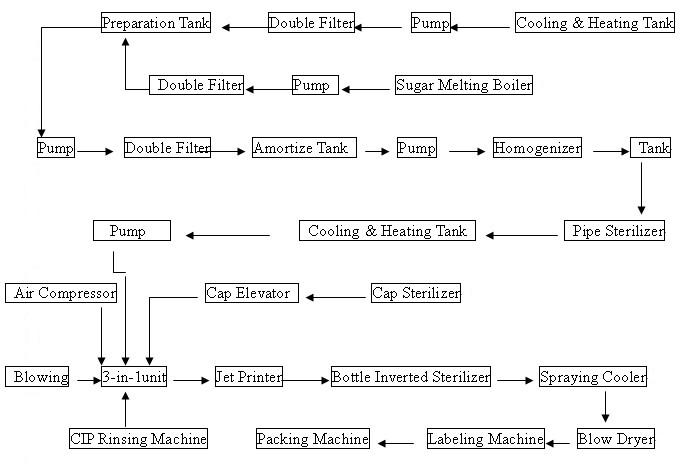

Technology Flow Chart of Tea

Production Line

Original Water Tank

Pump

Multi-medium Filter

YY-JDL Multi-medium filter is

mainly to remove the Particulate

Contamination, suspended

material, colloidal and other

materials in the water. The

filter filled with quartz sand,

coal and so on .The high of the

materials is usually 1200mm,the

size of the filter material, the

height of the layer all filled

according to the technological

requirements, then through the

Dosing disposal, through

debugging it can achieve

satisfactory results, let the

outlet water SDI lower.

Active Carbon Filter

YY-CHT Active carbon filter is

used to adsorbed the remaining

chlorine, organics, some

pigments and other harmful

substances in the raw water,

deduce the containing of the

COD. The filter filled with the

active carbon, the height of the

material is 1200mm.

Sodium Ion Exchanger

YY-SNJ Sodium ion exchanger is

for reducing the hardness of

hard water raw water goes

through the exchanger from top

to bottom, to be softened by the

sodium ion exchanger inside the

device. The positive ions of

magnesium and calcium are

exchanged with that of sodium.

Then the raw water becomes soft

water containing very few ions

of magnesium and calcium. The

soft water can be used for

feeding water of boiler and for

some industrial uses. Due to its

high dissolving ability in

water, sodium ions will not form

hard sediment in the boiler and

can be easily removed. Raw water

shall be filtered and set with

almost on suspended before

coming into the exchanging

device. After being softened in

the device, the water’s hardness

shall be less than 0.03mag

equivalent.

Precision Filter

YY-JML precision filter is

designed for dinking water

treatment. It can clear away

alien color and foreign

substance from the water and can

remove heavy metal such as

mercury, lead, cadmium, Zink,

iron, manganese and chromium,

and hydrogenate, small amount of

remaining chlordane so on.

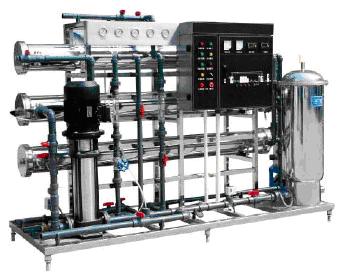

Reverse Osmosis Device

YY-FST reverse osmosis device is

an equipment to purify the

saline water with the action of

pressure difference of semi

permeable membrane. It is called

reverse osmosis, as it is

counter to natural penetration

direction. Different materials

have different osmotic

pressures. The reverse osmosis

method to adopt larger osmotic,

purify and condense.

Ozone Generator

YY-ZM ultraviolet sterilizer has

features of killing bacteria,

virus, yeast, mould, algae in

water using ultraviolet. It can

be widely used and up to the

effect of disinfection because

it doesn’t need adding any

chemicals and any heating or

cooling.

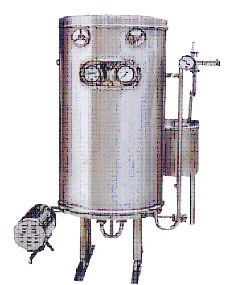

Preparation Tank

Model: YY-LB-1000

Production Capacity:1000L/time

Sugar Melting Boiler

YY-DHT -500 electrothermal sugar

melting boiler melts sugar into

syrup through electrothermal

tube.

Production Capacity:500L/time

Syrup Filter

Model: YY-TML-0.5 The TML series

syrup filter is used to filter

syrup. Production Capacity:500kg

Double Filter

Homogenizer

Cooling & Heating Tank

Ultra-temperature Sterilizer

CIP Rinsing Machine

Hot Filling

Washing-Filling-Capping Unit

|

Model |

YY-RCGF16-12-6 |

|

Production Capacity

(B/H) |

4000-5000(500ml) |

|

Diameter of Bottle

(mm) |

φ50-φ100 |

|

Height of Bottle

(mm) |

150-310 |

|

Power (KW) |

3.13 |

|

Overall Dimension

(mm) |

2100×1650×2300 |

|

Weight (kg) |

2500 |

Conveying System

Cap Elevator

Air Compressor

Jet Printer

|

Letterform lattice |

7×6,8×12,12×12,16×16,24×24 |

|

Print lines |

1-3lines (Can be

adjusted) |

|

Height of letter |

1.25-15MM(Can be

adjusted) |

|

Speed of print |

2M/S (single

line7×6) |

|

Print content |

Chinese,English,Arabia

and mark |

|

Power |

50W 220V 50-60HZ |

|

Air source flow |

20L/Min |

|

Outer dimension |

470×250×585MM |

|

Can receive BMP

picture edited by

computer |

Bottle Inversion Sterilize

|

Output |

100-250 bottle/min

|

|

Application scope |

Plastic bottles,

glass bottle |

|

Sterilizing time |

12-40s |

|

Chain speed |

4.5-25m/min |

|

Motor power |

1.5KW |

|

Weight |

1800kg |

Spraying Cooler

|

Model |

YY-PL-1 |

|

Production capacity

(b/m) |

80-120 |

|

Highest

sterilization

temperature (℃) |

100 |

|

Surface speed of

conveyer belt

(mm/min) |

110-553 |

|

Circular water

volume (m3/h) |

15 |

|

Pressure of steam

min pipe (Mpa) |

0.4 |

|

Overall dimension

(mm) |

600x1350x1650 |

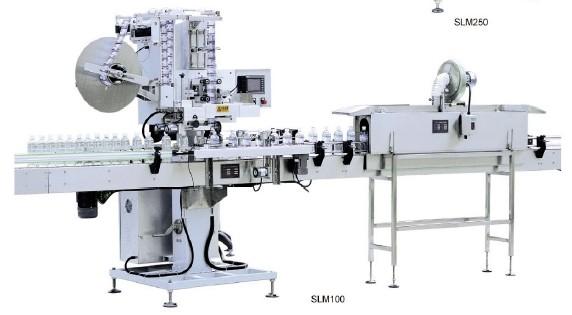

Automatic Labeling &

Shrinking Machine

|

Model |

YY-SLM-100 |

|

Capacity

(bottle/min) |

100 |

|

Bottle Diameter (mm) |

φ50-φ90 |

|

Suitable Label

Material |

PVC PET OPP OPS |

|

Label Thickness (mm) |

0.035~0.10 |

|

Overall Dimension

(mm) |

2400×950×2100 |

|

Weight (kg) |

450kg |

Blow Dryer

|

Power |

Overall Dimension |

Weight |

|

3kw |

1500×560×1400 |

150kg |

Automatic Packing Machine

|

Overall Dimension (L×W×H) |

5050×3300×2100 |

|

Heat Shrinking

Passage Dimension (L×W×H) |

3700×920×1800 |

|

Maximum Packing

Dimension (L×W×H) |

600×400×350 |

|

Speed of Packing

(packs/min) |

8-12 |

|

Height of Conveying

Belt |

920 |

|

Power of Working

Electricity |

380V 20KW

Three-Phase and

Five-Lines |

|

Working Pressure |

0.6-0.8Mpa |

Cap Sterilizer

|

Model |

Power |

Overall Dimension |

Capacity |

|

YY-XDG-1 |

80w |

600×500×1050 |

5000-6000pcs/h |

Machinery of Tea Drinks

Processing Display

Water Tank

Double-Connecting Filter

Quality-Average Machine

High Temperature Sterilizer

Cold & Hot Cylinder

Triad Machine

Cap Disinfection Cabinet

Bottle Regulating Machine

Spraying & Cooling Machine

Blow-Drying Machine

Date Printer

Shrink & Packing Machine

YY-RCGF Series Hot

Filling 3-In-1 Unit

Usage: The series equipment is

used in hot filling and sealing

of green tea,black tea and fruit

juice.The machine integrates

washing.filling and capping

together.The design is

scientific and reasonable with

good-looking appearance.Its

operation and maintenance is

convenient and is highly

automatic .It is good equipment

for hot drinks filling.

Main Technical parameter

|

Model |

YY-RCGF16-12-6 |

YY-RCGF18-18-6 |

YY-RCGF24-24-8 |

YY-RCGF32-32-12 |

YY-RCGF40-40-15 |

|

Production capacity

(500ml) |

4000-5000 |

6000-8000 |

8000-10000 |

10000-12000 |

12000-14000 |

|

Washing heads |

16 |

18 |

24 |

32 |

40 |

|

Filling heads |

12 |

18 |

24 |

32 |

40 |

|

Capping heads |

6 |

6 |

8 |

12 |

15 |

|

Suitable bottle size |

Circular or square

|

|

Diameter of bottle |

Φ50-Φ90 |

|

Height of bottle |

150-310 |

|

Compressed air pressure |

0.3-0.7 |

|

Washing medium |

Sterile water |

|

Washing pressure |

0.25 |

|

Power (KW) |

3.13 |

3.84 |

4.1 |

5.6 |

7.5 |

|

Overall dimension (MM) |

2100x1650x2300 |

2400x1900x2300 |

2800x2100x2300 |

4200x2300x2300 |

5000x2800x2400 |

|

Weight |

2500 |

3000 |

4000 |

5000 |

7500 |

YY-PL Shower Sterilizer

& Cooler

Main technical parameter

|

Model |

YY-PL-1 |

YY-PL-2 |

YY-PL-3 |

|

Production capacity

(b/m) |

80-120 |

150-180 |

200-250 |

|

Highest sterilization

temperature (℃) |

100 |

100 |

100 |

|

Surface speed of

conveyer belt (mm/min) |

110-553 |

200-1000 |

250-1500 |

|

Circular water volume

(m3/h) |

15 |

25 |

35 |

|

Pressure of steam min

pipe (Mpa) |

0.4 |

0.4 |

0.4 |

|

Overall dimension (mm) |

600x1350x1650 |

8000x1500x1650 |

1200x1700x1650 |

YY-DJ series beater

The equipment is used in beating

,discarding residue of fruit or

vegetable material.

Main Technical parameter

|

Production capacity |

2-4T/H |

|

Power |

3KW |

|

Weight |

350KG |

|

Overall dimension (mm) |

1950x750x1400 mm |

|

Diameter of mesh |

single: 1mm,

double:1mm,0.6mm |

YY-DS Automatic Bottle

Invented Sterilizer

It

is mainly used in sterilizing

PET bottle mouth and inside

surface of caps. In which

haven't been disinfected by the

mat tea, Fruit juice which

having been filled in PET

bottle. It mainly consist of

chief conveying chain system,

support, bottle reversing chain

system, bottle reversing guiding

rod and bottle repositioning

rod. Use its inner thermal

medium to disinfect bottle mouth

and caps without any other heat

source, So it can save energy.

The machine is fully made of

SUS304stainless steel, more

convenient in operation.

Main technical parameter

|

Output |

100-250 bottle/min

|

|

Application scope |

Plastic bottles,

glass bottle |

|

Sterilizing time |

12-40s |

|

Chain speed |

4.5-25m/min |

|

Motor power |

1.5KW |

|

Weight |

1800kg |

YY-GFP Series Negative

Pressure Filler

|

Model |

YY-GFP-12 |

YY-GFP-24 |

YY-GFP-32 |

|

Production capacity |

1500-2500B/H |

3000-5000B/H |

6000-8000B/H |

Bottle/can type

Inner dia. at inlet

Outer dia. of bottle

Bottle height

|

Glass bottle

Φ15-Φ18

Φ60-Φ80

200-320 |

PET bottle

Φ15-Φ18

Φ60-Φ80

200-320 |

Pop-top bottle

Φ15-Φ18

Φ60-Φ80

200-320 |

|

Power |

0.75 |

1.1 |

1.5 |

|

Overall dimension |

1000x800x2000 |

1330x1260x2200 |

1450x1700x2500 |

|

Weight |

1200 |

1600 |

2000 |