3000BPH(500ML) Ice Tea Juice

Filling Production Line

Project Proposal

This proposal is preliminary,

subject to final agreement after

technical and commercial

communication.

Ⅰ.

About YIYUAN

Ⅱ.

Our main products

Ⅲ.

Equipment and price list

Ⅳ.

Equipment parameters and

pictures

Ⅴ.

Business term

Ⅰ.

About YIYUAN

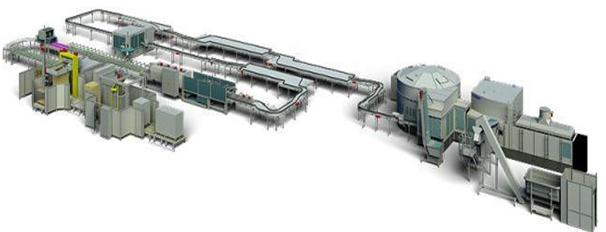

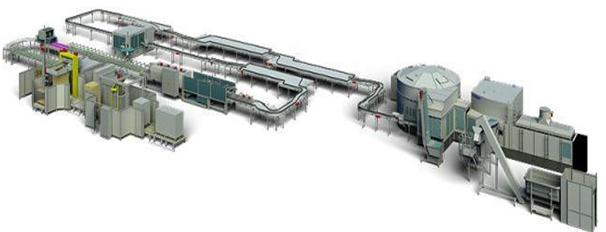

Ⅱ.Our Main Products

|

No. |

Item |

Remark |

Capacity |

|

1 |

Blowing-Filling-Capping

Combiblock |

Plastic Bottle |

12000-48000BPH |

|

2 |

Rotary Blow Molding Machine |

Plastic Bottle |

12000-48000BPH |

|

3 |

Hot Filling Line |

Plastic Bottle |

5000-48000BPH |

|

4 |

Ultra-clean Filling Line |

Plastic Bottle |

12000-36000BPH |

|

5 |

Ultra-clean (ESL) Filling Line |

Plastic Bottle |

5000-36000BPH |

|

6 |

Bottled Water Filling Line |

Plastic Bottle |

5000-48000BPH |

|

7 |

Big Bottle Water Filling Line |

3L-10L Plastic Bottle |

2000-8000BPH |

|

8 |

CSD Filling Line |

Plastic Bottle |

5000-36000BPH |

|

9 |

CSD Filling Line |

Glass Bottle |

5000-36000BPH |

|

10 |

CSD Filling Line |

Can |

9000-36000BPH |

|

11 |

Condiment (Soy sauce, Vinegar) Filling Line |

Plastic Bottle |

8000-36000BPH |

|

12 |

Condiment (Soy sauce, Vinegar) Filling Line |

Plastic Bottle |

8000-36000BPH |

|

13 |

Edible Oil Filling Line |

3L-10L

PET Bottle |

1000-12000BPH |

|

14 |

Liquid Household & personal Care Products Filling Line |

Plastic Bottle |

3000-24000BPH |

|

15 |

Beer Filling Line |

Plastic Bottle |

5000-36000 BPH |

|

16 |

Beer Filling Line |

Glass Bottle |

12000-6000 BPH |

|

17 |

Beer Filling Line |

|

9000-36000BPH |

|

18 |

Barreled Water Filling Line |

3 Gallon/5 Gallon |

300-3000BPH |

|

19 |

Water Treatment System |

Mineral/Pure Water |

5-100T/H |

|

20 |

Beverage Pre-treatment System |

|

5-60T/H |

Ⅲ.

Equipment and price list

Part1. 2T

Water Treatment System

|

NO. |

PRODUCT |

QYT |

PRICE(USD) |

|

1 |

Raw water pump |

1set |

25,016 |

|

2 |

Quartz sand filter

Ø470 |

1set |

|

3 |

Active carbon

filterØ470 |

1set |

|

4 |

Sodium ion

filterØ470 |

1set |

|

5 |

Precise filter Ø320 |

1set |

|

6 |

2T RO system(one-stage) |

1set |

|

7 |

Ozone generator |

1set |

|

8 |

Water storage

tank 2t |

1set |

|

9 |

Pump |

2sets |

|

10 |

Pipeline |

1set |

Part2.

2000L/H Juice Mixing system

|

NO. |

PRODUCT |

QTY |

PRICE(USD) |

|

1 |

Sugar melting pot

500L |

1set |

89,596 |

|

3 |

Syrup filter 1T |

1set |

|

4 |

1000L Mixing tank |

2sets |

|

5 |

Double filter |

1set |

|

6 |

500L Buffer tank |

2sets |

|

7 |

2T High pressure

homogenizer |

1set |

|

8 |

2T Vacuum deaerator |

1set |

|

9 |

2T Ultra-temperature

instantaneous

sterilizer |

1set |

|

10 |

1000L Insulation

tank |

2sets |

|

11 |

Beverage

Pump |

3sets |

|

12 |

300L CIP washing

machine |

1set |

|

13 |

Pipeline,fittings,valve

(with backwash) |

1set |

Part3. 3

in 1 Juice

Filling

Machine

|

NO |

PRODUCT |

QTY |

PRICE(USD) |

|

1. |

Air conveyor |

2m |

32,800 |

|

2. |

CGF8-8-3 Juice

filling machine |

1set |

|

3. |

Cap loader |

1set |

|

4. |

Light checker |

1set |

|

5. |

Conveyor |

2m |

Part4. Semi-automatic

Packing System

|

NO. |

PRODUCT |

QTY |

PRICE(USD) |

|

1. |

Bottle

dryer |

1set |

32,345 |

|

2. |

Inkjet code printer |

1set |

|

3. |

Semi-auto

sleeve-label machine |

1set |

|

4. |

Semi-auto PE film

packing machine |

1set |

|

5. |

Conveyor |

10m |

|

Subtotal |

|

Total FOB

Shanghai: USD179,755.00

Note:The

quotation is based on

380V/50HZ,3 phases,if you have

special requirements,please let

me know.

Ⅳ.

Equipment parameters and

pictures(pictures are just for

reference)

|

Part1. 2000L/H Water

Treatment System |

|

1. |

Raw water pump |

1set |

|

Ø Model:

CDL4-20

Ø Material:

pump stainless steel

SUS304

Ø Flow:

2m³/H

Ø Flow

length: 32m

|

|

2. |

Quartz sand filter |

1set |

|

The left one in

above picture

Usage: Mainly

used to remove the

algae, suspended

solids, colloid, etc

Ø Height:

2000mm

Ø Diameter:

470mm

Ø Material:

stainless steel

(Food grade)—made in

China

Ø Component:

water to send, water

collection, pressure

gauge, filtration

material. Valves,

etc

Ø Filter

media: Quartz sand

Ø Filter

volume:

2m³/h

|

|

3. |

Active carbon filter |

1set |

|

The middle one in

above picture

Usage: Mainly

used to remove water

odor, residual

chlorine, chloride

and heavy metals,

reduce color and

optimize water

quality.

Ø Model:

HML-2

Ø Height:

2000mm

Ø Diameter:

470mm

Ø Material:

stainless steel

(food grade)mirror

polishing—made in

China

Ø Component:

water to send, water

collection, pressure

gauge, filtration

material, Valves,

etc

Ø Media:

active carbon

Ø Processing

capacity:

2m³/h |

|

4. |

Sodium ion filter |

1set |

|

The right one in

above picture

Usage: Mainly

used to remove water

calcium magnesium

ions

Ø Model:

SNJ-2

Ø Height

: 2000mm

Ø Diameter:

470mm

Ø Material:

SUS304 stainless

steel(food

grade)—made in China

Ø Component:

water to send, water

collection, pressure

gauge, valve

materials, acid

exchange resin,

dissolve

measurement, valves,

etc

Ø Media:

Acid exchange resin

Ø Deal

volume:

2m³/h |

|

5. |

Precision filter |

1set |

|

Usage:

Mainly used to

remove water tiny

impurities.

Ø Model:

JML-2

Ø Height:

1400mm

Ø Diameter:

320mm

Ø Material:

SUS304 stainless

steel (food

grade)—stainless

steel

Ø Filter

precision: 5μm

Ø Deal

volume:

2m³/h

Ø Open

the filter to remove

impurities

|

|

6. |

2T

Reverse

Osmosis system(One

grade) |

1set |

|

Usage:This

device is used to

eliminate harmful

bacteria, the

inorganic ions,

organic ions, Remove

heavy metals and

salt; Adjust water

structure. It is an

ideal equipment and

high standards of

pure water.

² Model:

FSJ -

2

² Main

design data: the

first rank of

reverse osmosis≥2m³

/h(25 ℃ ) Element:

Project components,

Stainless steel

high-pressure

membrane shells, two

sets of Reverse

osmosis

high-pressure pump,

Nangfang pump

² Original

water(tap water,

surface

water,underground

water) pass

pretreatment

,sophisticated

filter,and then sent

to reverse osmosis

by high pressure

pump to produce pure

water directly that

is known as

one-stage reverse

osmosis.

² One-stage

reverse osmosis is

suitable for the

original water with

conductivity less

than 500 us/cm and

conductivity of

output water is 1-10

us/cm.

Component

² Stainless

steel high pressure

film shell

² All

kinds of capacity

indicator, pressure

indicator,

electricity magnetic

valve, balance

device and pipe

valve system

² Online

type pressure auto

self-protection

device

² Online

type electricity

indicator (with

stable compensation)

² System

safe protecting and

alarm system

² System

frame

² Working

process demonstrator |

|

7. |

Ozone generator |

1set |

|

Ø The

product is mainly

used in tap water,

mineral water, pure

water, beverage

water.

Ø Working

pressure: ≤0.08Mpa

Ø Ozone

concentration:

20mg/L

Ø Ozone

capacity: 8g/h

|

|

8. |

Water storage tank |

2sets |

|

Ø Aim:

Storing water

Ø Volume:

2 tons

Ø Material:

Food grade stainless

steel 304.

|

|

9. |

Pump

|

1set |

|

Ø Material:

High quality

stainless steel 304

Ø Power:

0.75kw

|

|

Part2.

2T

Juice Mixing

System |

|

2. |

Sugar melting pot |

1set |

|

Usage: The

mixing tank is used

for mixing water,

fruit juice

penetrate, and syrup

together through

stirring.

Ø Model:

PL-500

Ø Quantity:

1 set

Ø Capacity:

500 kilograms one

piece one time

Ø Diameter:

1000mm

Ø Height:

1500mm

Ø Framework

material: Food grade

stainless steel 304

|

|

2. |

Syrup filter |

1

set |

|

Usage: The

syrup filter is used

for removing dreg

from the syrup made

by sugar melting

pot. After the

felting the syrup

becomes clear and

pure. It’s essential

equipment for the

fruit juice

production.

Ø Model:

JML-1000

Ø Capacity:

1000

kilograms one time

Ø Size:

200mm*1000mm

Ø Framework

material: Food grade

stainless steel 304

|

|

3. |

Mixing tank 1T |

2

sets |

|

Ø Model:

PL-1000

Ø Capacity:

1000 kilograms one

piece one time

Ø Diameter:

1000mm

Ø Height:

1500mm

Ø Framework

material: Food grade

stainless steel 304

|

|

4. |

Double filter |

1

set |

|

Usage: The

double filter are

used to flit fresh

milk, sugar fluid,

drink, liquid

cement, Chinese

medicine fluid etc

to remove each kind

of slight pellet

impurity in liquid

accurately. It has

advantages like

flitting quick, low

cost, easy operation

etc.

Ø Model:

ZHP-1

Ø Size:

250mm*800mm*1200mm

Ø Framework

material: Food grade

SUS304

|

|

5. |

Temporary tank |

2 sets |

|

Ø Model:

WSG-500

Ø Volume:

500L

Ø Material:

Food grade SUS304

|

|

6. |

High pressure

homogenizer 2T |

1

set |

|

Ø Model:

GJB25-2

Ø Rated

pressure: 25Mpa

Ø Rated

flow:

2 m³/h

Ø Material

temperature: ≤85℃

Ø Pipe

diameter of inlet

orifice: ¢25mm

Ø Pipe

diameter of

discharge hole:

¢15mm

Ø Motor

power: 11kw

Ø L*W*H:1030mm*680mm*1120mm

|

|

7. |

Vacuum deaerator 2T |

1

set |

|

Usage: The

vacuum deaerator is

an indispensable

piece of equipment

in the production

line of juice and

tea. It is mainly

used for the

deaeration of

homogenized juice in

vacuum so as to

avoid the oxidation

to prolong its

preservation.

Ø Model:

TQ-2000

Ø Treatment

capacity:

2000

kg/h

Ø Framework

material: Food grade

stainless steel 304

|

|

8. |

Ultra-temperature

instantaneous

sterilizer |

1 set |

|

Usage: The

ultra-temperature

instantaneous

sterilizing machine

is used to sterilize

to the juice by

instantaneous

super-temperature

heating.

Ø Capacity:

2 ton

per hour

Ø Framework

material: Food grade

stainless steel 304

|

|

9. |

Insulation tank |

2

sets |

|

Ø Model:

LRG-1000

Ø Volume

for one tank: 1000L

Ø Framework

material: Food grade

SUS304.

|

|

10. |

Pump |

3sets |

|

Ø Material:

High quality

stainless steel 304

Ø Power:

0.75kw

|

|

11. |

Semi-automatic CIP

system |

1

set |

|

Ø Volume:

300L

Ø Power:

2.2KW

Ø The

CIP system is

responsible for

washing operation of

filling machine.

|

|

Part3. 3

in 1 Juice

Filling

Machine |

|

1. |

Air conveyor |

2m |

|

Usage: the

air conveyor is used

to convey the PET

bottle into the

filling machine,

hanging the neck of

the PET bottle. Can

connect with bottle

blow molding

machine, which

making PET bottle.

Main parameter

Ø Model:

FS-2

Ø Material:

Stainless steel

SUS304, made in

china

Ø Length:

2m

Ø Manner

of bottle inputting:

Bottle handling with

air delivering.

Ø Power

of motor: 0.75KW

|

|

2. |

CGF8-8-3 Juice

filling machine |

1set |

|

Usage: washing,

filling and

capping

3 in

1 monoblock is used

for filling

juice

into PET bottle.

Full automatically;

it can finish

washing, filling and

capping

three jobs

in the one machine.

Primary features

² Compact

conformation, good

shape, cozy

operation, excellent

automaticity and

poor labor

intensity.

² Only

exchanging “star

wheel”, ”feeding

screw” and “arc

guide plate” while

exchanging model of

bottle to be need.

² The

all parts directly

contacted with media

are all adopted with

food stage stainless

steel without dead

angle, so they can

be cleaned easily.

² Adopting

advanced valve to

control the inlet

flow rate of

liquids. It can keep

the slight

turbulence of

liquids level in the

solution barrel and

ensure the accuracy

in filling.

² Closing

feeding valve

automatically while

no bottle on machine

avoiding the loss of

aqueous feet.

Filling

automatically with a

high speed and the

control of liquids

level is accurate.

² High

filling speed and

mass flow rate, high

precision of filling

valve and control of

liquids level is

accurate and without

loss.

² The

“capping head” is

adopted

magnetic-constant-torque

device to ensure the

high capping quality

and without damages.

² Adopting

efficient cap

settling system

which carried

perfect cap feeding

and protection

device.

² It

is adopted spiral

descent fashion for

the support plate

for bottom of bottle

at the outlet

thumb wheel. And to

adjust the input

height is not

necessary for

exchanging model of

bottle.

² Carried

the perfect

protection system to

overload; it can be

used to protect

facilities and

operators

efficiently.

² Because

of applying touch

screen for

operation, it is

possible to realize

man-machine

conversation whereas

the status of device

running is clear at

a glance.

² The

primary electric

components such as

touch

screen\PLC\transducer

etc. are all adopted

with world famous

products.

Main parameter:

² Model:

CGF8-8-3

² Automatic

grade:Fully-automatic

² Resource

Power: AC380V, 50Hz,

three phases

² Washing

heads:8

² Filling

heads:8

² Capping

heads:3

² Theoretically capacity:

3000BPH for 500ML

Plastic bottle

² Volume

of PET bottle: 0.2L-1L

² PET

bottle standard(mm):

bottle neck diameter:

50-100mm

Max

Bottle body

diameter: 108mm

Bottle

height: 130-320mm

² Cap

diameter: plastic

screw type; cap

diameter from

28-38m(If bottle is

other size, it needs

to customize)

² Filling

precision:

≤±5mm(liquid level)

² Water

pressure of washing

bottle:0.18Mpa

² Water

consumption for

water

bottle:1600kg/h

² Gas

source pressure:0.6Mpa

² Gas

consumption:

0.3m³/min

² Total

power: 5.88kw

² Total

weight: 2500kg

² Dimension:

2100*1500*2200mm

Main configuration

|

NO |

NAME |

BRAND |

MANUFACTURER |

|

1 |

pneumatic

component |

Airtac |

Taiwan |

|

2 |

PLC |

Mitsubishi |

Japan |

|

3 |

Frequency

converter |

Mitsubishi |

Japan |

|

4 |

Touch

screen |

weinview |

Taiwan |

|

5 |

AC

contactor |

Delxi |

China |

|

5 |

Photoelectric

switch |

Autonics |

South

Korea |

|

6 |

Proximity

switch |

Autonics |

South

Korea |

|

8 |

Motor |

Sanli |

China |

|

9 |

Pump |

Nanfang |

China |

Washing Part

All 304 stainless

steel washing heads,

water spray style

inject design, more

save water

consumption & more

clean

304 Stainless steel

Gripper with plastic

pad, ensure minimal

bottle crash during

washing

304 stainless steel

washing pumps

Filling Part

The filling station

using all metal (not

plastic) 304

stainless steel

contact parts gives

consistent accurate,

high precision

filling nozzle

together with vacuum

pump regurgitate

system, to ensure

the high filling

precision, ensure

same filling level

Centre 304L

stainless steel

filling nozzle used

which are designed

for maximum flow

rate and minimum

bottle distortion

during filling.

All 304 stainless

steel contact parts

& liquid tank, fine

polish, no death

corner, easy to

clean

Capping Part

Place & capping

system,

electromagnetic

capping heads, with

burden discharge

function, make sure

minimum bottle crash

during capping

All 304stainless

steel construction

No bottle no

capping,

Automatic stop when

lack of caps

|

|

3. |

Cap loader |

1set |

|

Usage: It

is used for

conveying caps into

the capping machine

by blowing. It

starts to work

automatically when

it is lake of cap in

the capping machine.

The height and

distance of

transporting caps,

the time of

sterilizing can be

adjusted as the

requirement.

Main parameter:

Ø Capacity:

2000

caps per hour

Ø Power

consumption for

loading motor: 0.37

kw

Ø Overall

dimension (L*W*H):

750*650*2200mm

Ø Framework

material: stainless

steel

|

|

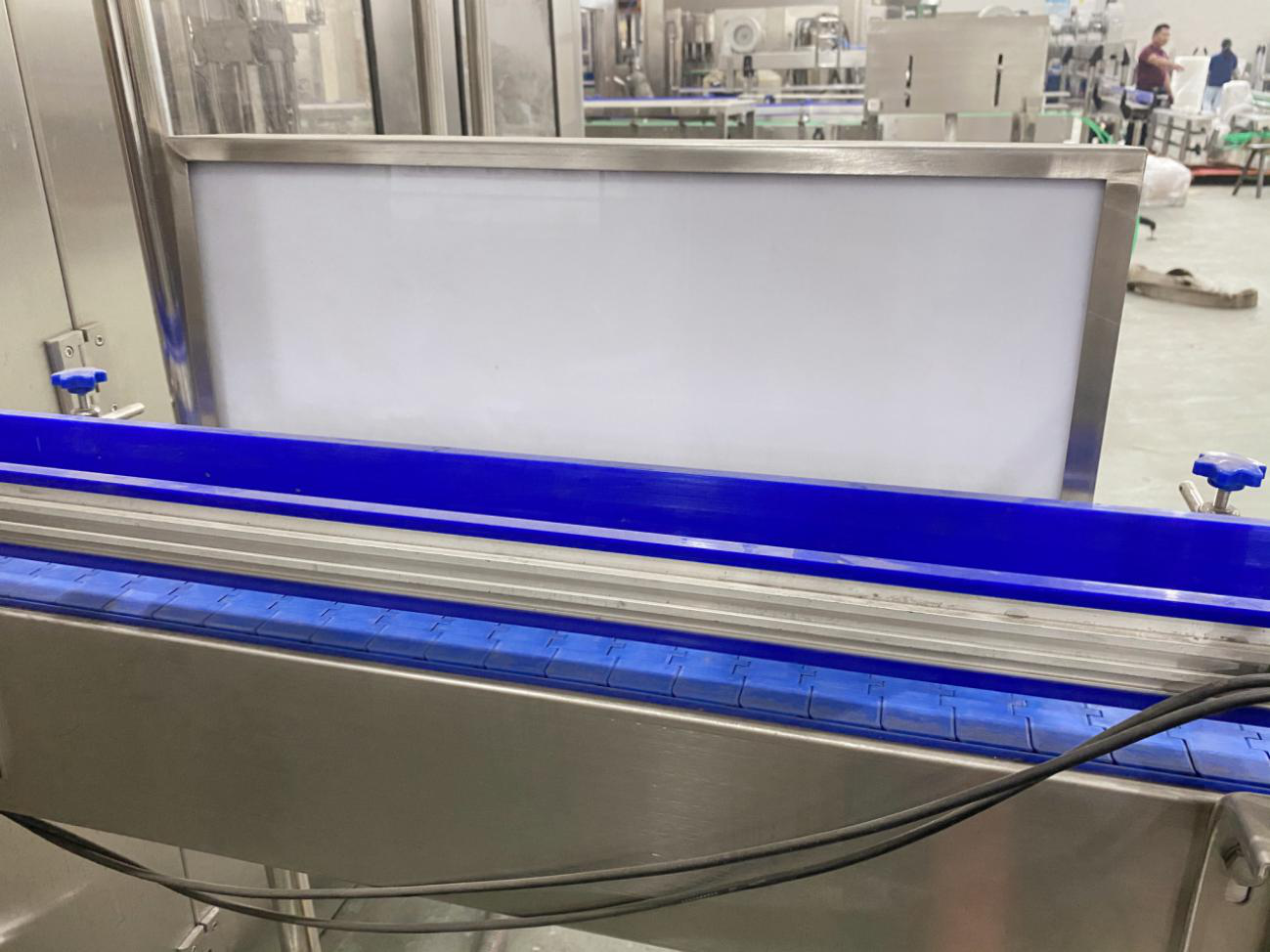

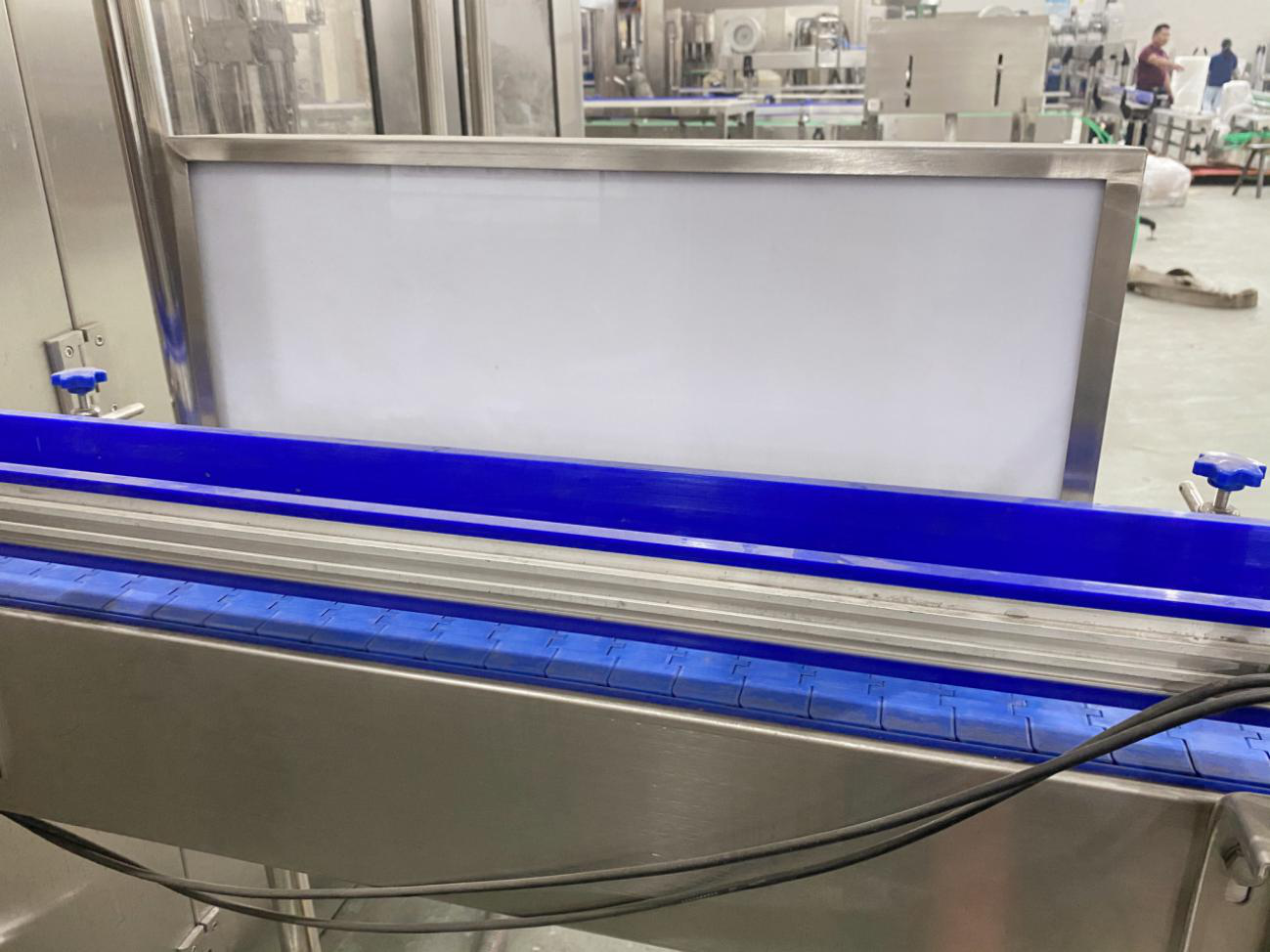

4. |

Light checker |

1set |

|

Main parameter:

Ø Lighting

tube quantity: 2

pieces

Ø Power

consumption: 2*3 kW

Ø Material

for framework:

stainless steel

|

|

5. |

Conveyor |

2m |

|

Ø Framework

material: stainless

steel

Ø Conveyor

belt material:

plastic

Ø Length:2m

|

|

Part4. Semi-automatic

Packing System |

|

1. |

Bottle dryer |

1

set |

|

Ø Framework

material: stainless

steel

Ø Conveyor

belt material:

plastic

Ø Length:2m

Usage:

The blowing dryer is

used for remove

water on the bottle

after filling, the

air is cleaned by

the special blower,

and the wind is

even.

Ø Capacity:

2000

bottles per hour

Ø Power

consumption: 4Kw

Ø Dimension

(L*W*H):

800mm*500mm*1500mm

Ø Framework

material: Food grade

SUS304

|

|

2 |

Semi-Automatic

shrinking labeling

machine |

1

set |

|

Heat shrink tunnel

Steam

generator

Usage: the

sleeving label table

is used for store

the bottles when the

workers sleeving the

labels on the

bottles, then when

the bottles with

label go through the

channel, they will

be heated then be

fixed on the

bottles.

Ø Capacity:

3000 bottles per

hour

Ø Sleeving-label-by-hand

table size: Length:

2000mm Width: 750mm

Ø Label

material: PVC/PET

Ø Boiler

power: 12kw

Ø Shrinking

label channel

length: 2m

Ø Framework

material for the

two: Stainless

steel 304

Heat shrink tunnel

Description:

It has an even

shrinking. The

distribution of Iow-pressure

steam drum and

spouting way of

steam are uniform

and designed with

seamless tube. The

nozzle is divided to

be adjustable three

segments and the

height, position and

steam output of

every segment can be

adjusted

respectively so as

to gain the perfect

shrinking effect.

The whole machine is

made of stainless

steel with heat

preservation, which

not only saves

energy, but also

complies with the

international safety

standard. The

stainless steel

defrosting tray

collects condense

water. The whole

machine adopts the

water-proof design

with the convenience

of easy operation

and low maintenance.

Technical parameter

Ø Working

Pressure:0.1Mpa

Ø Steam

consumption:10-15kg/h

Ø dimension:

L75mm x W30mm x

H40mm

Ø Weight:30kg

Ø Framework

material: SUS304

Steam generator

Description:

This steam generator

is run by power

energy, no noise, no

pollution,using high

quality heating

elements,with a

lower surface heat

load and a higher

thermal

efficiency.This

product adopts

separate cabinate

design style,

elegant appearance,

compact internal

structure and it’s

also ideal for

saving space.

Technical parameter:

Ø Rated

team capacity:13kg/H

Ø Rated

working

pressure:0.7mpa

Ø Hydraulic

test pressure:1.1Mpa

Ø Steam

pressure for

use:0.1-0.6Mpa

Ø Rated

steam

temperature:170°C

Ø Thermal

efficiency:98%

Ø Input

power:9kw

Ø Dimension:

750×550×920mm

Ø Net

weight:75kg |

|

3 |

Automatic inkjet

printer |

1

set |

|

Ø Model:

Lead jet A100 (made

in China)

Ø Height

of Character: 100

type spout (20mm)

Ø Character

Types: ASCII code

Ø Spraying

Speed: 0.5

meter/minutes~60meter/minutes

(Max capacity for

bottles: 10000

bottles per hour)

Ø Interface:

RS-232C

Ø Memory

Info: 80 documents

Ø Software

Function: the

character is

adjustable, the

printing can be

delayed, the width

of the character,

the direction of the

printing, the

reversion of the

character,

enlargement of the

character, cleanout

automatically .etc.

Ø Operating

environment:

38F~122F

Ø Printing

Ink: Diversified

spraying ink (water

craft, oil craft)

Ø Printing

Material: Osmosis

and non-osmosis

Ø Spraying

Distance: 5-30mm |

|

4 |

Semi-Automatic

shrink packing

machine |

1

set |

|

Usage: the

machine is used for

packing bottled

water, drink, or

canned drink into a

pack with PE film.

When the pack is

finished by hand,

coming through the

machine, it will be

pack solid. Don’t

need backing board

or paper plate when

packing; it will

save the cost of

packing. It is

widely used in

production of

mineral water, pure

water, soft drink,

beer, juice and so

on.

Capacity: 1-2 bags

per minute

Features:

² Unique

thermal passage with

2 sets of

centrifugal thermal

air circulation

system that has an

equal heat

distribution with

beautiful and secure

shrinkage effect.

² 3

layers of heat

insulation treatment

with good insulating

property, quick

temperature rise and

energy saving.

² The

enhanced cooling

shaping passage can

quickly turn the

packaging membrane

into high strength

status that is

conveniently stored

and transported.

² It

is easy to change

the packaging

combination and

bottle type to

integrate the

multi-function into

one machine |

|

5. |

Conveyor

|

10m |

|

Ø Framework

material: stainless

steel

Ø Conveyor

belt material:

plastic

Ø Length:10m

|

Ⅴ.

Business term

|

GENERAL CONTRACT

CONDITIONS |

|

VALIDITY |

: |

180 days since January

26, 2020. |

|

SHIPMENT |

: |

60 working

days after receipt of

order and down payment |

|

PAYMENT TERMS |

: |

-30% T/T at sight at the

order

-70% T/T at sight before

delivery |

|

PORT OF LOADING |

: |

Shanghai, China |

|

PACKING |

: |

This production line

will be packaged by

wooden case; each

machine will be packing

by stretched film and

fixed with iron wire in

container. |

|

WARRANTY |

: |

l Mechanical

parts: 12 months from

delivery.

l Electric

motors:

12 months

from delivery or

manufacture's warranty.

l Electromechanical

components and

instruments:

12 months

from delivery or

manufacture's warranty.

|

|

SERVICE |

|

1 |

Warranty period is 12

months from the date of

shipment. |

|

2 |

After we receipt 30%

advance deposit, we will

start to produce. When

the machine is

completed, buyers come

to observe and test

machine by themselves,

until the machine is

running OK, we will

arrange the shipment

after the buyer pay for

the other 70% balance. |

|

3 |

The seller should supply

the parts which is

damaged non-contrived

and is included in the

standard configuration

of this machine without

any charges. The seller

pay for freight in

China, and the buyer

should pay the freight

out of China. |

|

4 |

The seller will send

technician to seller to

maintain the machine

within one week after

receiving the visa to

your company during the

warranty period of this

machine. |

|

5 |

The seller should supply

spare parts and service

of maintenance to buyer

out of warranty period,

but the buyer should pay

for the cost of parts

and freight out of China

and pay the roundtrip

tickets between China

and buyer, lodging and

dinner, medical

treatment, etc.

|

|

6 |

The buyer should get all

conditions (raw

material, water, power,

compress air and tools)

for installation and

commissioning well

before seller’s

technician arrives at

buyer’s factory. |

|

7 |

The seller should supply

buyer the documents for

installation and

commissioning within 5

days after contract is

available, other related

documents will be

supplied to buyer before

shipment. |

|

8 |

The seller should send

two or three technicians

to buyer’s company make

installation and

commissioning of this

machine. The time of

installation and

commissioning is 30 days

from the date which

seller’s technicians

arrive at buyer’s

factory and the seller

prepare well all

conditions for

installation and

commissioning.

The buyer should pay for

the charges of visa

cost, roundtrip ticket,

lodging, meal and

Inland traffic to

seller’s technician. And

give each technician

salary

100

USD one day. |

|

9 |

The seller supply

training service for

buyer without any

charges before shipment,

and can train buyer’s

technicians continuously

when seller’s

technicians install and

adjust the machine. |

-END-

|